- 2012 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2003 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2004 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2009 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2001 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2010 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1996 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2005 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2007 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2008 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1999 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2002 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2000 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2011 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1998 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 1997 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- 2006 Nissan Frontier Owners Manuals

- Nissan Frontier Owners Manuals

- Download PDF Manual

-

specifically designed for use in your ve- hicle model. See your NISSAN dealer for more information.

● Properly position the mats in the floor- well using the floor mat positioning aid. See ⴖFloor mat positioning aidⴖ in this section.

The use of genuine NISSAN floor mats can ex- tend the life of your vehicle carpet and make it easier to clean the interior. Mats should be main- tained with regular cleaning and replaced if they become excessively worn.

SEAT BELTS The seat belts can be cleaned by wiping them with a sponge dampened in a mild soap solution. Allow the belts to dry completely in the shade before using them. See “Seat belt maintenance” in the “Safety – Seats, seat belts and supplemen- tal restraint system” section of this manual.

WARNING

Do not allow wet seat belts to roll up in the retractor. NEVER use bleach, dye or chemical solvents to clean the seat belts, since these materials may severely weaken the seat belt webbing.

CORROSION PROTECTION

MOST COMMON FACTORS CONTRIBUTING TO VEHICLE CORROSION ● The accumulation of moisture-retaining dirt and debris in body panel sections, cavities, and other areas.

● Damage to paint and other protective coat- ings caused by gravel and stone chips or minor traffic accidents.

ENVIRONMENTAL FACTORS INFLUENCE THE RATE OF CORROSION Moisture Accumulation of sand, dirt and water on the ve- hicle body underside can accelerate corrosion. Wet floor coverings will not dry completely inside the vehicle and should be removed for drying to avoid floor panel corrosion. Relative humidity Corrosion will be accelerated in areas of high relative humidity, especially those areas where the temperatures stay above freezing and where atmospheric pollution exists and road salt is used.

Appearance and care 7-5

LAI0009

Floor mat positioning aid This vehicle includes two driver’s side front floor mat brackets and one passenger’s side front floor mat bracket to help keep your floor mats in place. Genuine NISSAN floor mats have been specially designed for your vehicle model. The driver’s side floor mat has two grommet holes incorporated in it and the passenger’s side has one grommet hole. Position each mat by placing the floor mat bracket hook through the floor mat grommet holes while centering the mat in the floorwell. Periodically check to make certain the mats are properly positioned.

Temperature High temperatures accelerate the rate of corro- sion to those parts which are not well ventilated. Air pollution Industrial pollution, the presence of salt in the air in coastal areas, or heavy road salt use acceler- ates the corrosion process. Road salt also accel- erates the disintegration of paint surfaces. TO PROTECT YOUR VEHICLE FROM CORROSION ● Wash and wax your vehicle often to keep the

vehicle clean.

● Always check for minor damage to the paint

and repair it as soon as possible.

● Keep drain holes at the bottom of the doors

open to avoid water accumulation.

● Check the underbody for accumulation of sand, dirt or salt. If present, wash with water as soon as possible.

CAUTION

● NEVER remove dirt, sand or other de- bris from the passenger compartment by washing it out with a hose. Remove dirt with a vacuum cleaner or broom.

● Never allow water or other liquids to come in contact with electronic compo- nents inside the vehicle as this may damage them.

Chemicals used for road surface de-icing are extremely corrosive. They accelerate corrosion and deterioration of underbody components such as the exhaust system, fuel and brake lines, brake cables, floor pan and fenders. In winter, the underbody must be cleaned periodically. For additional protection against rust and corro- sion, which may be required in some areas, con- sult a NISSAN dealer.

7-6 Appearance and care

8 Maintenance and do-it-yourself

Maintenance requirements. . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

General maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Explanation of general maintenance items . . . . . . . . . 8-2

Maintenance precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Engine compartment check locations . . . . . . . . . . . . . . . . 8-6

Engine cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Checking engine coolant level . . . . . . . . . . . . . . . . . . . 8-9

Changing engine coolant . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Checking engine oil level . . . . . . . . . . . . . . . . . . . . . . . 8-10

Changing engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Changing engine oil filter . . . . . . . . . . . . . . . . . . . . . . . 8-12

5-speed automatic transmission fluid . . . . . . . . . . . . . . . 8-13

Power steering fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Brake and clutch (if so equipped) fluid . . . . . . . . . . . . . . 8-14

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Clutch fluid (if so equipped) . . . . . . . . . . . . . . . . . . . . 8-15

Windshield-washer fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Windshield-washer fluid reservoir . . . . . . . . . . . . . . . 8-15

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Jump starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Variable voltage control system. . . . . . . . . . . . . . . . . . . . . 8-17

Drive belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18Spark plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Replacing spark plugs . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

In-cabin microfilter (if so equipped) . . . . . . . . . . . . . . 8-20

Windshield wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Passenger compartment . . . . . . . . . . . . . . . . . . . . . . . 8-25

Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Keyfob (if so equipped) . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Exterior and interior lights. . . . . . . . . . . . . . . . . . . . . . . 8-30

Wheels and tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Tire pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Tire labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

Types of tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

Tire chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Changing wheels and tires . . . . . . . . . . . . . . . . . . . . . 8-39MAINTENANCE REQUIREMENTS

GENERAL MAINTENANCE

Your NISSAN has been designed to have mini- mum maintenance requirements with long ser- vice intervals to save you both time and money. However, some day-to-day and regular mainte- nance is essential to maintain your NISSAN’s good mechanical condition, as well as its emis- sions and engine performance.

It is the owner’s responsibility to make sure that the scheduled maintenance, as well as general maintenance, is performed.

As the vehicle owner, you are the only one who can ensure that your vehicle receives proper maintenance. You are a vital link in the mainte- nance chain. Scheduled maintenance

For your convenience, both required and optional scheduled maintenance items are described and listed in your “NISSAN Service and Maintenance Guide”. You must refer to that guide to ensure that necessary maintenance is performed on your NISSAN at regular intervals. General maintenance

General maintenance includes those items which should be checked during normal day-to-day op- eration. They are essential for proper vehicle op- eration. It is your responsibility to perform these maintenance procedures regularly as prescribed. 8-2 Maintenance and do-it-yourself

Performing general maintenance checks requires minimal mechanical skill and only a few general automotive tools. These checks or inspections can be done by you, a qualified technician, or, if you prefer, a NISSAN dealer. Where to go for service If maintenance service is required or your vehicle appears to malfunction, have the systems checked and corrected by a NISSAN dealer. NISSAN technicians are well-trained specialists who are kept up-to-date with the latest service information through technical bulletins, service tips, and in-dealership training programs. They are completely qualified to work on NISSAN ve- hicles before they work on your vehicle, rather than after they have worked on it. You can be confident that a NISSAN dealer’s service department performs the best job to meet the maintenance requirements on your vehicle — in a reliable and economical way.

During the normal day-to-day operation of the vehicle, general maintenance should be per- formed regularly as prescribed in this section. If you detect any unusual sounds, vibrations or smells, be sure to check for the cause or have a NISSAN dealer do it promptly. In addition, you should notify a NISSAN dealer if you think that repairs are required.

When performing any checks or maintenance work, closely observe the “Maintenance precau- tions” later in this section. EXPLANATION OF GENERAL MAINTENANCE ITEMS Additional information on the following items with “ * ” isfound later in this section. Outside the vehicle The maintenance items listed here should be performed from time to time, unless otherwise specified. Doors and engine hood Check that the doors and engine hood operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, latch pins, rollers and links as necessary. Make sure that the secondary latch keeps the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrication frequently. Lights* Clean the headlights on a regular basis. Make sure that the headlights, stop lights, tail lights, turn signal lights, and other lights are all operating properly and installed securely. Also check headlight aim. Road wheel nuts (lug nuts)* When checking the tires, make sure no wheel nuts are missing, and check for any loose wheel nuts. Tighten if necessary. Tire rotation* Tires should be rotated every 7,500 miles (12,000 km). Tires* Check the pressure with a gauge often and always prior to long distance trips. If neces- sary, adjust the pressure in all tires, including the spare, to the pressure specified. Check carefully for damage, cuts or excessive wear. Tire Pressure Monitoring System (TPMS) transmitter components Replace the TPMS transmitter grommet seal, valve core and cap when the tires are replaced due to wear or age. Wheel alignment and balance If the vehicle should pull to either side while driving on a straight and level road, or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds, wheel balancing may be needed. ● For additional

information regarding tires, refer to “Important Tire Safety Information” (US) or “Tire Safety Information” (Canada) in the Warranty Information Booklet.

Windshield Clean the windshield on a regular basis. Check the windshield at least every six months for cracks or other damage. Have a dam- aged windshield repaired by a qualified repair facility. Windshield wiper blades* Check for cracks or wear if they do not wipe properly. Inside the vehicle The maintenance items listed here should be checked on a regular basis, such as when per- forming periodic maintenance, cleaning the ve- hicle, etc. Additional information on the following items with an “*” is found later in this sec- tion.

Accelerator pedal Check the pedal for smooth operation and make sure the pedal does not bind or require uneven effort. Keep the floor mat away from the pedal.

Automatic transmission P (Park) position mechanism On a fairly steep hill check that your vehicle is held securely with the shift selector in the P (Park) position without applying any brakes. Brake pedal Check the pedal for smooth opera- tion. If the brake pedal suddenly goes down fur- ther than normal, the pedal feels spongy or the vehicle seems to take longer to stop, see a NISSAN dealer immediately. Keep the floor mat away from the pedal. Brakes Check that the brakes do not pull the vehicle to one side when applied. Parking brake Check the parking brake opera- tion regularly. The vehicle should be securely held on a fairly steep hill with only the parking brake applied. If the parking brake needs adjustment, see a NISSAN dealer. Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to ensure they operate smoothly and all latches lock securely in every position. Check that the head restraints and headrests move up and down smoothly and the locks (if so equipped) hold securely in all latched positions.

Maintenance and do-it-yourself 8-3

Seat belts Check that all parts of the seat belt system (for example, buckles, anchors, adjusters and retractors) operate properly and smoothly, and are installed securely. Check the belt web- bing for cuts, fraying, wear or damage. Steering wheel Check for changes in the steer- ing system, such as excessive freeplay, hard steering or strange noises. Warning lights and chimes Make sure all warning lights and chimes are operating properly. Windshield wiper and washer* Check that the wipers and washer operate properly and that the wipers do not streak. Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient quantity when operating the heater or air conditioner. Under the hood and vehicle The maintenance items listed here should be checked periodically (for example, each time you check the engine oil or refuel). Battery* Check the fluid level It should be between the MAX and MIN lines. Ve- hicles operated in high temperatures or under severe conditions require frequent checks of the battery fluid level. 8-4 Maintenance and do-it-yourself

in each cell.

Brake and clutch fluid levels* Make sure that the brake and clutch fluid level is between the MIN and MAX lines on the reservoir. Engine coolant level* Check the coolant level when the engine is cold. Engine drive belts* Make sure the drive belts are not frayed, worn, cracked or oily. Engine oil level* Check the level after parking the vehicle on a level surface with the engine off. Wait more than 10 minutes for the oil to drain back into the oil pan. Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the exhaust seems unusual or there is a smell of exhaust fumes, immediately have the exhaust system inspected by a NISSAN dealer. See the carbon monoxide warning in the “Starting and driving” section of this manual. Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has been parked for a while. Water dripping from the air conditioner after use is normal. If you should notice any leaks or if gasoline fumes are evident, check for the cause and have it corrected imme- diately.

Power steering fluid level* and lines Check the level when the fluid is cold, with the engine off. Check the lines for proper attachment, leaks, cracks, etc. Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may have accumulated. Make sure the hoses have no cracks, deformation, rot or loose connections. Underbody The underbody is frequently ex- posed to corrosive substances such as those used on icy roads or to control dust. It is very important to remove these substances from the underbody, otherwise rust may form on the floor pan, frame, fuel lines and exhaust system. At the end of winter, the underbody should be thor- oughly flushed with plain water, in those areas where mud and dirt may have accumulated. See the “Appearance and care” section of this manual. Windshield-washer fluid* Check that there is adequate fluid in the reservoir.

MAINTENANCE PRECAUTIONS

When performing any inspection or maintenance work on your vehicle, always take care to prevent serious accidental injury to yourself or damage to the vehicle. The following are general precau- tions which should be closely observed.

WARNING

● Park the vehicle on a level surface, ap- ply the parking brake securely and block the wheels to prevent the vehicle from moving. Move the shift selector to P (Park).

● Be sure the ignition switch is in the OFF or LOCK position when performing any parts replacement or repairs.

● If you must work with the engine run- ning, keep your hands, clothing, hair and tools away from moving fans, belts and any other moving parts.

● It is advisable to secure or remove any loose clothing and remove any jewelry, such as rings, watches, etc. before working on your vehicle.

● Always wear eye protection whenever

you work on your vehicle.

● Your vehicle is equipped with an auto- matic engine cooling fan. It may come on at any time without warning, even if the ignition switch is in the OFF posi- tion and the engine is not running. To avoid injury, always disconnect the negative battery cable before working near the fan.

● If you must run the engine in an en- closed space such as a garage, be sure there is proper ventilation for exhaust gases to escape.

● Never get under the vehicle while it is supported only by a jack. If it is neces- sary to work under the vehicle, support it with safety stands.

● Keep smoking materials,

flame and sparks away from the fuel tank and battery.

● On gasoline engine models, the fuel filter or fuel lines should be serviced by a NISSAN dealer because the fuel lines are under high pressure even when the engine is off.

CAUTION

● Do not work under the hood while the engine is hot. Turn the engine off and wait until it cools down.

● Avoid contact with used engine oil and coolant. Improperly disposed engine oil, engine coolant and/or other vehicle fluids can damage the environment. Al- ways conform to local regulations for disposal of vehicle fluid.

● Never leave the engine or automatic transmission related component har- nesses disconnected while the ignition switch is in the ON position.

● Never connect or disconnect the battery or any transistorized component while the ignition switch is in the ON position.

This “Maintenance and do-it-yourself” section gives instructions regarding only those items which are relatively easy for an owner to perform. You should be aware that incomplete or improper servicing may result in operating difficulties or excessive emissions, and could affect warranty coverage. If in doubt about any servicing, have it done by a NISSAN dealer.

Maintenance and do-it-yourself 8-5

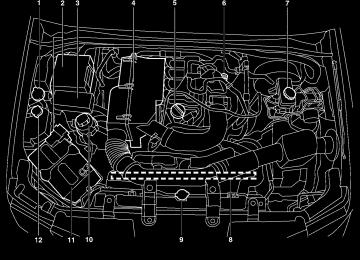

ENGINE COMPARTMENT CHECK LOCATIONS

8-6 Maintenance and do-it-yourself

WDI0643

QR25DE engine 1. Windshield-washer fluid reservoir 2. 3. 4. 5. 6. 7.

Fuse/Fusible link box Fuse and relay box Air cleaner Engine oil filler cap Engine oil dipstick Brake fluid reservoir/Clutch fluid reservoir (M/T model) Drive belt location Radiator cap

8. 9. 10. Power steering fluid reservoir 11. Battery 12. Engine coolant reservoir NOTE: Engine cover removed for clarity.

VQ40DE engine 1. Windshield-washer fluid reservoir 2. 3. 4. 5. 6.

Fuse/fusible link box Fuse and relay box Engine oil filler cap Engine oil dipstick Brake fluid reservoir/Clutch fluid reservoir (M/T model) Air cleaner Drive belt location Radiator cap

7. 8. 9. 10. Power steering fluid reservoir 11. Battery 12. Engine coolant reservoir NOTE: Engine cover removed for clarity.

LII0167

Maintenance and do-it-yourself 8-7

● The life expectancy of the factory-fill coolant is 105,000 miles (168,000 km) or 7 years. Mixing any other type of cool- ant other than Genuine NISSAN Long Life Antifreeze/Coolant (blue), includ- ing Genuine NISSAN Long Life Antifreeze/Coolant (green), or the use of non-distilled water will reduce the life expectancy of the factory-fill cool- ant. Refer to the Nissan Service and Maintenance Guide for more details.

ENGINE COOLING SYSTEM

The engine cooling system is filled at the factory with a pre-diluted mixture of 50% Genuine NISSAN Long Life Antifreeze/Coolant (blue) and 50% water to provide year-round anti-freeze and coolant protection. The antifreeze solution con- tains rust and corrosion inhibitors. Additional en- gine cooling system additives are not necessary.

WARNING

● Never remove the radiator or coolant reservoir cap when the engine is hot. Wait until the engine and radiator cool down. Serious burns could be caused by high pressure fluid escaping from the radiator. See precautions in “If your vehicle overheats” found in the “In case of emergency” section of this manual. ● The radiator is equipped with a pres- sure type radiator cap. To prevent en- gine damage, use only a genuine NISSAN radiator cap.

CAUTION

(blue)

● When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Antifreeze/Coolant or equivalent. Genuine NISSAN Long Life Antifreeze/Coolant (blue) is pre-diluted to provide antifreeze protection to -34° F (-37° C). If additional freeze protec- tion is needed due to weather where you operate your vehicle, add Genuine NISSAN Long Life Antifreeze/Coolant (blue) concentrate following the direc- tions on the container. If an equivalent coolant other than Genuine NISSAN Long Life Antifreeze/Coolant (blue) is used, follow the coolant manufacturer’s instructions to maintain minimum anti- freeze protection to -34° F (-37° C). The use of other types of coolant solutions other than Genuine NISSAN Long Life Antifreeze/Coolant (blue) or equivalent may damage the engine cooling system.

8-8 Maintenance and do-it-yourself

VQ40DE

QR25DE

LDI0436

LDI0466

CHECKING ENGINE COOLANT LEVEL Check the coolant level in the reservoir when the engine is cold. If the coolant level is below the MIN level, add coolant to the MAX level. If the reservoir is empty, check the coolant level in the radiator when the engine is cold. If there is insufficient coolant in the radiator, fill the radiator with coolant up to the filler opening and also add it to the reservoir up to the MAX level. This vehicle contains Genuine NISSAN Long Life Antifreeze/Coolant (blue). The life expectancy of the factory-fill coolant is 105,000 miles (168,000

km) or 7 years. Mixing any other type of coolant or the use of non-distilled water will reduce the life expectancy of the factory-fill coolant. Refer to the NISSAN Service and Maintenance Guide for more details. The engine coolant reservoir is a pressur- ized tank. When installing the cap, tighten it until a clicking sound is heard. If the cooling system frequently requires coolant, have it checked by a NISSAN dealer.

CHANGING ENGINE COOLANT A NISSAN dealer can change the engine coolant. The service procedure can be found in the NISSAN Service Manual. Improper servicing can result in reduced heater performance and engine overheat- ing.

WARNING

● To avoid the danger of being scalded, never change the coolant when the en- gine is hot.

● Never remove the radiator or engine coolant reservoir cap when the engine is hot. Serious burns could be caused by high pressure fluid escaping from the radiator.

● Avoid direct skin contact with used coolant. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

● Keep coolant out of the reach of chil-

dren and pets.

Engine coolant must be disposed of properly. Check your local regulations.

Maintenance and do-it-yourself 8-9

ENGINE OIL

VQ40DE

QR25DE

WDI0672

LDI0467

CHECKING ENGINE OIL LEVEL 1. Park the vehicle on a level surface and apply

the parking brake.

2. Start the engine and let it idle until it reaches

operating temperature.

3. Turn off the engine. Wait more than 10

minutes for the oil to drain back into the oil pan.4. Remove the dipstick and wipe it clean. Re-

insert it all the way.

8-10 Maintenance and do-it-yourself

LDI0371

5. Remove the dipstick again and check the oil level. It should be between the H (High) and L (Low) marks 䊊B . This is the normal oper- ating oil level range. If the oil level is below the L (Low) mark 䊊A , remove the oil filler cap and pour recommended oil through the opening. Do not overfill 䊊C .6. Recheck oil level with the dipstick. It is normal to add some oil between oil maintenance intervals or during the break-in period, depending on the severity of operating conditions.

CAUTION

Oil level should be checked regularly. Op- erating the engine with an insufficient amount of oil can damage the engine, and such damage is not covered by warranty.

VQ40DE

QR25DE

WDI0500

WDI0501

CHANGING ENGINE OIL 1. Park the vehicle on a level surface and apply

the parking brake.

2. Start the engine and let it idle until it reaches

operating temperature, then turn it off.

3. Remove the oil filler cap 䊊A by turning it

counterclockwise.

4. Place a large drain pan under the drain plug. 5. Remove the drain plug 䊊B with a wrench by turning it counterclockwise and completely drain the oil.

If the oil filter is to be changed, remove and replace it at this time. See “Changing engine oil filter” in this section.

● Waste oil must be disposed of prop-

erly.

● Check your local regulations.

Maintenance and do-it-yourself 8-11

The drain and refill capacity depends on the oil temperature and drain time. Use these specifications for reference only. Always use the dipstick to determine when the proper amount of oil is in the engine.

8. Start the engine. Check for leakage around the drain plug and oil filter. Correct as re- quired.

9. Turn the engine off and wait more than 10

minutes. Check the oil level with the dipstick. Add engine oil if necessary.WARNING

● Prolonged and repeated contact with used engine oil may cause skin cancer. ● Try to avoid direct skin contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

● Keep used engine oil out of reach of

children.

CAUTION

Be careful not to burn yourself. The engine oil may be hot.

6. Clean and reinstall the drain plug and a new washer. Securely tighten the drain plug with a wrench. Do not use excessive force. Drain plug tightening torque: 22 - 29 ft-lb (29 - 39 N·m)

7. Refill engine with recommended oil through the oil filler opening, then install the oil filler cap securely.

and

“Capacities

See recommended fuel/lubricants” in the “Technical and con- sumer information” section of this manual for drain and refill capacity.

8-12 Maintenance and do-it-yourself

VQ40DE

WDI0502

CHANGING ENGINE OIL FILTER 1. Park the vehicle on a level surface and apply

the parking brake.

2. Turn the engine off.

3. Place a large drain pan under the oil filter.

4. Unscrew the plate covering the oil filter ex- posing the filter. (For VQ40DE engine only) filter wrench by turning it counterclockwise. Then remove the oil filter by turning it by hand.

filter 䊊A with an oil

5. Loosen the oil

5-SPEED AUTOMATIC TRANSMISSION FLUID

7. Coat the gasket on the new filter with clean

engine oil.

When checking or replacement is required, we recommend your NISSAN dealer for servicing.

8. Screw on the oil filter until a slight resistance

is felt, then tighten an additional 2/3 turn.

9. Start

the engine and check for leakage

around the oil filter. Correct as required.

10. Turn the engine off and wait more than 10

minutes. Check the oil level. Add engine oil if necessary.WDI0503

QR25DE

CAUTION

Be careful not to burn yourself. The engine oil may be hot.

6. Wipe the engine oil filter sealing surface with

a clean rag.

CAUTION

Be sure to remove any old gasket material remaining on the sealing surface of the engine. Failure to do so could lead to engine damage.

CAUTION

● Use Genuine NISSAN Matic S ATF. If Genuine NISSAN Matic S ATF is not available, Genuine NISSAN Matic J ATF may also be used.

● Using automatic transmission fluid other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deteriora- tion in driveability and automatic trans- mission durability, and may damage the automatic transmission, which is not covered by the NISSAN new vehicle lim- ited warranty.

The specified automatic transmission fluid is also described on caution labels located in the engine compartment.

Maintenance and do-it-yourself 8-13

POWER STEERING FLUID

WDI0256

The fluid level should be checked using the HOT MAX range on the power steering fluid reservoir at fluid temperatures of 122° - 176°F (50° - 80°C) or using the COLD MAX range on the power steering fluid reservoir at fluid tempera- tures of 32° - 86°F (0° - 30°C). If the fluid is at or below the MIN line, add Genu- ine NISSAN PSF. Remove the cap and fill through the opening.CAUTION

BRAKE AND CLUTCH (if so equipped) FLUID

For further brake and clutch fluid specification information, to “Capacities and recom- mended fuel/lubricants” in the “Technical and consumer information” section of this manual.

refer

WARNING

● Use only new fluid from a sealed con- tainer. Old, inferior or contaminated fluid may damage the brake and clutch (if so equipped) systems. The use of improper fluids can damage the brake and clutch system and affect the vehi- cle’s stopping ability.

● Clean the filler cap before removing. ● Brake and clutch fluid is poisonous and should be stored carefully in marked containers out of reach of children.

CAUTION

Do not spill the fluid on any painted sur- faces. This will damage the paint. If fluid is spilled, immediately wash the surface with water.

LDI0463

BRAKE FLUID Check the brake fluid level in the reservoir. If the fluid level is below the MIN line or the brake warning light comes on, add Genuine NISSAN Super Heavy Duty Brake Fluid or equivalent DOT 3 fluid up to the MAX line. If fluid must be added frequently, the system should be checked by a NISSAN dealer.

● DO NOT OVERFILL. ● Recommended

is NISSAN PSF or equivalent.

fluid

Genuine

8-14 Maintenance and do-it-yourself

WINDSHIELD-WASHER FLUID

LDI0463

LDI0441

CLUTCH FLUID (if so equipped) Check the clutch fluid level in the reservoir (manual transmissions only). If the fluid level is below the MIN line, add Genuine NISSAN Super Heavy Duty Brake Fluid or equivalent DOT 3 fluid up to the MAX line. If fluid must be added fre- quently, the system should be checked by a NISSAN dealer. For further brake and clutch fluid specification information, to “Capacities and recom- mended fuel/lubricants” in the “Technical and consumer information” section of this manual.

refer

WINDSHIELD-WASHER FLUID RESERVOIR Fill the windshield-washer fluid reservoir periodi- cally. Add windshield-washer fluid when the low windshield-washer (if so equipped) comes on.

fluid warning light

To fill the windshield-washer fluid reservoir, lift the cap off the reservoir and pour the windshield- washer fluid into the reservoir opening.

Add a washer solvent to the washer for better cleaning. In the winter season, add a windshield washer antifreeze. Follow the manufacturer’s in- structions for the mixture ratio.

Refill the reservoir more frequently when driving conditions require an increased amount of windshield-washer fluid. Recommended fluid is Genuine NISSAN Wind- shield Washer Concentrate Cleaner & Anti- freeze or equivalent.

CAUTION

● Do not substitute engine anti-freeze coolant for windshield-washer solution. This may result in damage to the paint. ● Do not fill the windshield-washer reser- voir with washer fluid concentrates at full strength. Some methyl alcohol based washer fluid concentrates may permanently stain the grille if spilled while filling the windshield-washer reservoir.

● Pre-mix washer fluid concentrates with water to the manufacturer’s recom- mended levels before pouring the fluid into the windshield-washer reservoir. Do not use the windshield-washer res- ervoir to mix the washer fluid concen- trate and water.

Maintenance and do-it-yourself 8-15

● Do not operate the vehicle if the fluid in the battery is low. Low battery fluid can cause a higher load on the battery which can generate heat, reduce bat- tery life, and in some cases lead to an explosion.

● When working on or near a battery, al- ways wear suitable eye protection and remove all jewelry.

● Battery posts, terminals and related ac- cessories contain lead and lead com- pounds. Wash hands after handling.

● Keep battery out of

children.

the reach of

● Do not tip the battery. Keep the vent

caps tight and the battery level.

WDI0224

1. Remove the vent caps with a screwdriver as shown. Use a cloth to protect the battery case.BATTERY

● Keep the battery surface clean and dry. Clean the battery with a solution of baking soda and water.

● Make certain the terminal connections are

clean and securely tightened.

● If the vehicle is not to be used for 30 days or longer, disconnect the negative (-) battery terminal cable to prevent discharge.

WARNING

● Do not expose the battery to flames, an electrical spark or a cigarette. Hydro- gen gas generated by the battery is ex- plosive. Explosive gases can cause blindness or injury. Do not allow battery fluid to contact your skin, eyes, fabrics or painted surfaces. Sulfuric acid can cause blindness or injury. After touch- ing a battery or battery cap, do not touch or rub your eyes. Thoroughly wash your hands. If the acid contacts your eyes, skin or clothing, immediately flush with water for at least 15 minutes and seek medical attention.

8-16 Maintenance and do-it-yourself

VARIABLE VOLTAGE CONTROL SYSTEM

Vehicles operated in high temperatures or under severe conditions require frequent checks of the battery fluid level. JUMP STARTING If jump starting is necessary, see “Jump starting” in the “In case of emergency” section of this manual. If the engine does not start by jump starting, the battery may have to be replaced. Contact a NISSAN dealer.

LDI0454

CAUTION

● Do not ground accessories directly to the battery terminal. Doing so will by- pass the variable voltage control sys- tem and the vehicle battery may not charge completely.

● Use electrical accessories with the en- gine running to avoid discharging the vehicle battery.

Your vehicle is equipped with a variable voltage control system. This system measures the amount of electrical discharge from the battery and controls voltage generated by the generator.

Maintenance and do-it-yourself 8-17

2. Check the fluid level

in each cell.

WDI0529

If it is necessary to add fluid, add only distilled water to bring the level up to the bottom of the filler opening. Do not overfill. Reinstall the vent caps.DRIVE BELT

The current sensor 䊊A is located near the battery along the negative battery cable. If you add elec- trical accessories to your vehicle, be sure to ground them to a suitable body ground such as the frame or engine block area.

VQ40DE

WDI0639

1. Visually inspect the belt for signs of unusual wear, cuts, fraying or looseness. If the belt is in poor condition or is loose, have it replaced or adjusted by a NISSAN dealer.

2. Have the belt checked regularly for condi- tion and tension in accordance with the maintenance the “NISSAN Service and Maintenance Guide”.

schedule

found

in

Power steering fluid pump Automatic belt tensioner

1. 2. 3. Cooling fan 4. 5. Crankshaft pulley 6. Generator

Air conditioner compressor

WARNING

Be sure the ignition key is in the OFF or LOCK position before servicing drive belt. The engine could rotate unexpectedly.

8-18 Maintenance and do-it-yourself

SPARK PLUGS

SDI1895

REPLACING SPARK PLUGS Platinum-tipped spark plugs It is not necessary to replace platinum-tipped 䊊A spark plugs as frequently as conventional type spark plugs because they last much longer. Fol- low the maintenance log shown in the “NISSAN Service and Maintenance Guide”. Do not service platinum-tipped spark plugs by cleaning or re- gapping. ● Always replace spark plugs with rec-

ommended or equivalent ones.

WARNING

Be sure the engine and ignition switch are off and that the parking brake is engaged securely.

CAUTION

Be sure to use the correct socket to re- move the spark plugs. An incorrect socket can damage the spark plugs.

Maintenance and do-it-yourself 8-19

QR25DE

LDI0461

Power steering fluid pump

1. 2. Water pump 3.

Air conditioner compressor (if so equipped)

4. Crankshaft pulley 5. Generator

AIR CLEANER

WARNING

● Operating the engine with the air cleaner removed can cause you or oth- ers to be burned. The air cleaner not only cleans the air, it stops the flame if the engine backfires. If it isn’t there, and the engine backfires, you could be burned. Do not drive with the air cleaner removed, and be careful when working on the engine with the air cleaner removed.

● Never pour fuel into the throttle body or attempt to start the engine with the air cleaner removed. Doing so could result in serious injury.

IN-CABIN MICROFILTER (if so equipped) The in-cabin microfilter restricts the entry of air- borne dust and pollen particles and reduces some objectionable outside odors. The filter is located behind the glove box. Refer to the “NISSAN Service and Maintenance Guide” for change intervals. To replace the filter, perform the following proce- dure:

VQ40DE

QR25DE

WDI0686

LDI0465

2. Push down half of air cleaner to clear the

bottom retainers.

3. Lift up on half of air cleaner to remove the air

cleaner filter

The air cleaner filter should not be cleaned and reused. Replace it according to the maintenance log shown in the “NISSAN Service and Mainte- nance Guide.” When replacing the filter, wipe the inside of the air cleaner filter housing and the cover with a damp cloth.

To remove the VQ40DE air cleaner filter: 䊊1 Push down on the clips and remove the air cleaner cover. Remove the air cleaner filter.

To remove the QR25DE air cleaner filter: 1. Unlatch the clips 䊊A , 䊊B , 䊊C .

8-20 Maintenance and do-it-yourself

LDI0442

1. Open the glove box and press in on the sides so that it will open completely allowing it to hang by the cord.LDI0676

2. Lift upward to release the filter cover andremove the filter cover.

LDI0473

NOTE: The filters are marked with air flow arrows. The end of the filter with the arrow should face the rear of the vehicle. The arrows should face downward. 3.

Insert the first filter into the housing and slide it over to the right. Insert the second filter into the housing.

4. Replace the filter cover. 5.

Install the glove box door.

Maintenance and do-it-yourself 8-21

6. Return the wiper to its original position and release it until it has made contact with the windshield.

CAUTION

● After wiper blade replacement, return the wiper arm to its original position; otherwise it may be damaged when the hood is opened.

● Make sure the wiper blades contact the glass; otherwise the arms may be dam- aged from wind pressure.

WINDSHIELD WIPER BLADES

CLEANING If your windshield is not clear after using the windshield washer or if a wiper blade chatters when running, wax or other material may be on the blade or windshield. Clean the outside of the windshield with a washer solution or a mild detergent. Your windshield is clean if beads do not form when rinsing with clear water. Clean each blade by wiping it with a cloth soaked in a washer solution or a mild detergent. Then rinse the blades with clear water. If your wind- shield is still not clear after cleaning the blades and using the wiper, replace the blades.

CAUTION

Worn windshield wiper blades can dam- age the windshield and impair driver vision.

8-22 Maintenance and do-it-yourself

WDI0408

REPLACING Replace the wiper blades if they are worn.

1. Lift the wiper arm away from the windshield. 䊊2 Push the release tab, then move the wiper

blade down the wiper arm to remove.

䊊3 Remove the wiper blade. 4.

Insert the new wiper blade onto the wiper arm until it clicks into place.

5. Rotate wiper blade so the dimple is in the

groove.

WDI0595

If you wax the surface of the hood, be careful not to let wax get into the windshield washer nozzle 䊊A . This may cause clogging or improper wind- shield washer operation. If wax gets into the nozzle, remove it with a needle or small pin 䊊B .BRAKES

If the brakes do not operate properly, have the brakes checked by a NISSAN dealer. Self-adjusting brakes Your vehicle is equipped with self-adjusting brakes.

The front and rear disc-type brakes self-adjust every time the brake pedal is applied.

WARNING

See a NISSAN dealer for a brake system check if the brake pedal height does not return to normal.

Brake pad wear indicators The disc brake pads on your vehicle have audible wear indicators. When a brake pad requires re- placement, a high pitched scraping or screech- ing sound will be heard when the vehicle is in motion. The noise will be heard whether or not the brake pedal is depressed. Have the brakes checked as soon as possible if the wear indicator sound is heard.

Under some driving or climate conditions, occa- sional brake squeak, squeal or other noise may be heard. Occasional brake noise during light to moderate stops is normal and does not affect the function or performance of the brake system.

Proper brake inspection intervals should be followed. For more information regarding brake inspections, see the appropriate mainte- nance schedule information in the “NISSAN Ser- vice and Maintenance Guide”.

Maintenance and do-it-yourself 8-23

FUSES

LDI0455

Two types of fuses are used. Type 䊊A is used in the fuse boxes in the engine compartment. Type 䊊B is used in the passenger compartment fuse box. Type A fuses are provided as spare fuses. They are stored in the passenger compartment fuse box. Type A fuses can be installed in the engine com- partment and passenger compartment fuse boxes.LDI0457

If a type A fuse is used to replace a type B fuse, the type A fuse will not be level with the fuse pocket as shown in the illustration. This will not affect the performance of the fuse. Make sure the fuse is installed in the fuse box securely. Type B fuses cannot be installed in the under- hood fuse boxes. Only use type A fuses in the underhood fuse boxes.LDI0444

ENGINE COMPARTMENT

CAUTION

Never use a fuse of a higher or lower amperage rating than specified on the fuse box cover. This could damage the electrical system or cause a fire.

If any electrical equipment does not come on, check for an open fuse.

1. Be sure the ignition switch and the headlight

switch are OFF.

2. Open the engine hood.

8-24 Maintenance and do-it-yourself

3. Remove the fuse box cover by pushing the

tab and lifting the cover up.

4. Remove the fuse with the fuse puller. The fuse puller is located in the center of the fuse block in the passenger compartment.

5.

6.

WDI0452

If the fuse is open 䊊A , replace it with a new fuse 䊊B . If a new fuse also opens, have the electrical system checked and repaired by a NISSAN dealer.Fusible links If the electrical equipment does not operate and fuses are in good condition, check the fusible links. If any of these fusible links are melted, replace with only Genuine NISSAN parts.

PASSENGER COMPARTMENT

LDI0445

CAUTION

Never use a fuse of a higher or lower amperage rating than specified on the fuse box cover. This could damage the electrical system or cause a fire.

If any electrical equipment does not operate, check for an open fuse. 1. Be sure the ignition switch and the headlight

switch are OFF.

2. Pull the fuse box cover to remove. 3. Remove the fuse with the fuse puller. Maintenance and do-it-yourself 8-25

BATTERY REPLACEMENT

CAUTION

Be careful not to allow children to swallow the battery or removed parts.

WDI0452

LDI0456

4.

Type A

If the fuse is open 䊊A , replace it with an equivalent good fuse 䊊B .

5. Push the fuse box cover to install. 6.

If a new fuse also opens, have the electrical system checked and repaired by a NISSAN dealer.

Type B

8-26 Maintenance and do-it-yourself

● Do not touch the internal circuit and electric

terminals as it could cause a malfunction.

● When changing the battery, do not let dust

or oil get on the keyfob.

● There is danger of explosion if a lithium bat- tery is incorrectly replaced. Replace only with the same or equivalent type.

Recommended battery: CR2025 or equivalent. 䊊4 Close the lid securely.

5. Press the

button, then the

button two or three times to check the key- fob operation.

If the battery is removed for any reason other than replacement, perform step 5.

● An improperly disposed battery can hurt the environment. Always confirm local regulations for battery disposal.

● The keyfob is water-resistant; how- ever, if it does get wet, immediately wipe completely dry.

● The operational range of the keyfob extends to approximately 33 ft (10 m) from the vehicle. This range may vary with conditions.

Maintenance and do-it-yourself 8-27

KEYFOB (if so equipped) Replace the battery in the keyfob as follows: 䊊1 Open the lid using a coin 䊊A . 䊊2 Remove the battery 䊊B .

䊊3

LDI0484

Install a new battery 䊊C with the “+” facing down.● Hold the battery by the edges. Holding the battery across the contact points will seri- ously deplete the storage capacity.

Fog may temporarily form inside the lens of the exterior lights in the rain or in a car wash. A temperature difference between the inside and the outside of the lens causes the fog. This is not a malfunction. If large drops of water collect inside the lens, contact a NISSAN dealer.

FCC Notice: Changes or modifications not expressly ap- proved by the party responsible for compli- ance could void the user’s authority to op- erate the equipment. This device complies with Part 15 of the FCC Rules and RSS-210 of Industry Canada. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, in- cluding interference that may cause undes- ired operation of the device.

8-28 Maintenance and do-it-yourself

LIGHTS

HEADLIGHTS The headlight is a semi-sealed beam type which uses a replaceable headlight (halogen) bulb. A bulb can be replaced from inside the engine compartment without removing the headlight as- sembly.

CAUTION

● High pressure halogen gas is sealed inside the halogen bulb. The bulb may break if the glass envelope is scratched or the bulb is dropped.

● When handling the bulb, do not touch

the glass envelope.

● DO NOT TOUCH THE BULB WITH BARE

HANDS.

● Use the same number and wattage as

shown in the chart.

● Do not leave the bulb out of the head- light reflector for a long period of time as dust, moisture and smoke may enter the headlight body and affect the per- formance of the headlight.

● Aiming is not necessary after replacing the bulb. When aiming adjustment is necessary, contact a NISSAN dealer.

4. Turn the bulb retaining ring counterclock- wise until it is free from the headlight reflec- tor and then remove it 䊊A .

5. Carefully remove the headlight bulb. Do not shake or rotate the bulb when removing it 䊊B .

Replacing the headlight bulb 1.

Insert the bulb. DO NOT TOUCH THE BULB WITH BARE HANDS. Install and tighten the bulb retainer. ● Be sure the lip of the bulb socket con-

2.

tacts the headlight body.

3. Push the electrical connector into the bulb

plastic base until it snaps and stops.

4. Connect the negative (-) battery cable. 5. Close the hood.

LDI0446

Removing the headlight bulb 1. Open the hood.

2. Disconnect the negative (-) battery cable. 3. Disconnect the electrical connector from the

rear end of the bulb.

Maintenance and do-it-yourself 8-29

EXTERIOR AND INTERIOR LIGHTS

Item

Headlight Turn signal light/Parking light Side marker Rear combination light

Turn signal Stop/Tail Back-up

Wattage (W)

65/55

28/8

3.827

27/8

18

55License plate light Fog light*2 (if so equipped) Map lights (if so equipped) Interior light High-mounted stop light/cargo light*2

*1Always check with the Parts Department at a NISSAN dealer for the latest parts information. *2The bulb is not serviceable in-vehicle. See a NISSAN dealer for assistance.12.8

Bulb No.*1

9007 (HB5)

T-20 NA

194

3156AK 3157K

921

W5W H11

AL38

AL41

912LFLDI0713

Interior light

1. Map lights (if so equipped) 2. 3. High-mounted stop light/cargo light 4. 5. 6. 7. Headlight assembly

License plate light Rear combination light Fog light (if so equipped)

8-30 Maintenance and do-it-yourself

Interior light

Use a cloth 䊊1 to protect the housing.

WDI0206

WDI0306

Replacement procedures All other lights are either type A, B, C or D. When replacing a bulb, first remove the lens and/or cover.

: Indicates bulb removal : Indicates bulb installation

Map lights/personal lights

LDI0459

Maintenance and do-it-yourself 8-31

WHEELS AND TIRES

If you have a flat tire, see “Flat tire” in the “In case of emergency” section of this manual. TIRE PRESSURE Tire Pressure Monitoring System (TPMS) This vehicle is equipped with the Tire Pressure Monitoring System (TPMS). It monitors tire pressure of all tires except the spare. When the low tire pressure warning light is lit and the CHECK TIRE PRES warning message is displayed in the odometer, one or more of your tires is significantly under-inflated. The TPMS will activate only when the vehicle is driven at speeds above 16 MPH (25 km/h). Also, this system may not de- tect a sudden drop in tire pressure (for example a flat tire while driving). For more details, refer to “Low tire pres- sure warning light” in the “Instruments and controls” section, “Tire Pressure Monitor- ing System (TPMS)” in the “Starting and driving” section, and “Flat tire” in the “In case of emergency” section.

Rear combination light

License plate light

WDI0300

WDI0411

8-32 Maintenance and do-it-yourself

Tire inflation pressure Check the tire pressures (including the spare) often and always prior to long dis- tance trips. The recommended tire pres- sure specifications are shown on the F.M.V.S.S./C.M.V.S.S. certification label or the Tire and Loading Information label under the “Cold Tire Pressure” heading. The Tire and Loading Information label is affixed to the driver side center pillar. Tire pressures should be checked regularly because: ● Most tires naturally lose air over time. ● Tires can lose air suddenly when driven over potholes or other objects or if the vehicle strikes a curb while parking.

The tire pressures should be checked when the tires are cold. The tires are considered COLD after the vehicle has been parked for 3 or more hours, or driven less than 1 mile (1.6 km) at moderate speeds.

Incorrect tire pressure, including un- der inflation, may adversely affect tire life and vehicle handling.

WARNING

● Before taking a long trip, or whenever you heavily load your vehicle, use a tire pressure gauge to ensure that the tire pressures are at the specified level.

● For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Information” (Canada) in the Warranty Infor- mation Booklet.

Safety

is

located on

● Improperly inflated tires can fail suddenly and cause an accident. ● The Gross Vehicle Weight Rating the (GVWR) F.M.V.S.S./C.M.V.S.S. certifica- tion label. The vehicle weight ca- pacity is indicated on the Tire and Loading Information label. Do not load your vehicle beyond this capacity. Overloading your ve- hicle may result in reduced tire life, unsafe operating conditions due to premature tire failure, or unfavorable handling character- istics and could also lead to a serious accident. Loading be- yond the specified capacity may also result in failure of other ve- hicle components.

Maintenance and do-it-yourself 8-33

䊊6 Spare tire size or compact spare tire

size (if so equipped).

Tire and loading information label 䊊1 Seating capacity: The maximum num- ber of occupants that can be seated in the vehicle.

䊊2 Vehicle load limit: See loading infor- mation in the “Technical and con- sumer information” section.

䊊3 Original tire size: The size of the tires originally installed on the vehicle at the factory.

8-34 Maintenance and do-it-yourself

LDI2007

䊊4 Cold tire pressure: Inflate the tires to this pressure when the tires are cold. Tires are considered COLD after the vehicle has been parked for 3 or more hours, or driven less than 1 mile (1.6

km) at moderate speeds. The recom- mended cold tire inflation is set by the manufacturer to provide the best bal- ance of tire wear, vehicle handling, driveability, tire noise, etc., up to the vehicle’s GVWR.䊊5 Tire size – refer to “Tire labeling” later

in this section.

4. Read the tire pressure on the gauge stem and compare to the specifica- tion the F.M.V.S.S./C.M.V.S.S. the Tire and Loading Information label.

on label or

shown

5. Add air to the tire as needed. If too much air is added, press the core of the valve stem briefly with the tip of the gauge stem to release pressure. Recheck the pressure and add or release air as needed. Install the valve stem cap.

6. 7. Check the pressure of all other tires,

including the spare.

LDI0393

Checking tire pressure 1. Remove the valve stem cap from the

tire.

2. Press the pressure gauge squarely onto the valve stem. Do not press too hard or force the valve stem side- ways, or air will escape. If the hissing sound of air escaping from the tire is heard while checking the pressure, reposition the gauge to eliminate this leakage.

3. Remove the gauge.

Size

Front Original Tire: P235/75R15

P265/70R16

P265/75R16

P265/60R18

Rear Original Tire: P235/75R15

P265/70R16

P265/75R16

P265/60R18

Spare Tire: P235/75R15

P265/70R16

P265/75R16

P265/60R18Cold Tire Infla- tion Pressure

240 kPa, 35 PSI

240 kPa, 35 PSI

240 kPa, 35 PSI

Maintenance and do-it-yourself 8-35

Example

WDI0394

TIRE LABELING Federal law requires tire manufacturers to place standardized information on the sidewall of all tires. This information iden- tifies and describes the fundamental characteristics of the tire and also pro- vides the tire identification number (TIN) for safety standard certification. The TIN can be used to identify the tire in case of a recall.

8-36 Maintenance and do-it-yourself

Example

WDI0395

䊊1 Tire size (example: P215/65R15 95H) 1. P: The “P” indicates the tire is de- signed for passenger vehicles (not all tires have this information).

2. Three-digit number (215): This num- ber gives the width in millimeters of the tire from sidewall edge to side- wall edge.

3. Two-digit number (65): This number, known as the aspect ratio, gives the tire’s ratio of height to width.

4. R: The “R” stands for radial. 5. Two-digit number (15): This number is the wheel or rim diameter in inches. 6. Two- or three-digit number (95): This number is the tire’s load index. It is a measurement of how much weight each tire can support. You may not find this information on all tires be- cause it is not required by law.

7. H: Tire speed rating. You should not drive the vehicle faster than the tire speed rating.

䊊2 TIN (Tire Identification Number) for a new tire (example: DOT XX XX XXX XXXX) 1. DOT: Abbreviation for the “Depart- ment Of Transportation”. The symbol can be placed above, below or to the left or right of the Tire Identification Number. 2. Two-digit

code: Manufacturer’s

identification mark.

3. Two-digit code: Tire size.

Example

WDI0396

4. Three-digit code: Tire type code

(Optional).

5. Three-digit code: Date of Manufac-

ture.

6. Four numbers represent the week and year the tire was built. For ex- ample, the numbers 3103 means the 31st week of 2003. If these numbers are missing, then look on the other sidewall of the tire.

䊊3 Tire ply composition and material The number of layers or plies of rubber- coated fabric in the tire. Tire manufactur- ers also must indicate the materials in the tire, which include steel, nylon, polyester, and others. 䊊4 Maximum permissible inflation pres- sure This number is the greatest amount of air pressure that should be put in the tire. Do not exceed the maximum permissible in- flation pressure. 䊊5 Maximum load rating This number indicates the maximum load in kilograms and pounds that can be car- ried by the tire. When replacing the tires on the vehicle, always use a tire that has the same load rating as the factory in- stalled tire. 䊊6 Term of “tubeless” or “tube type” Indicates whether the tire requires an in- ner tube (“tube type”) or not (“tubeless”).

Maintenance and do-it-yourself 8-37

䊊7 The word “radial” The word “radial” is shown if the tire has radial structure. 䊊8 Manufacturer or brand name Manufacturer or brand name is shown. Other Tire-related Terminology In addition to the many terms that are defined throughout this section, Intended Outboard Sidewall is (1) the sidewall that contains a whitewall, bears white lettering or bears manufacturer, brand, and/or model name molding that is higher or deeper than the same molding on the other sidewall of the tire, or (2) the out- ward facing sidewall of an asymmetrical tire that has a particular side that must always face outward when mounted on a vehicle.

8-38 Maintenance and do-it-yourself

TYPES OF TIRES

WARNING

● When changing or replacing tires, be sure all four tires are of the same type (i.e., Summer, All Season or Snow) and construction. A NISSAN dealer may be able to help you with information about tire type, size, speed rating and availability.

● Replacement tires may have a lower speed rating than the factory equipped tires, and may not match the potential maximum vehicle speed. Never exceed the maximum speed rating of the tire.

● For additional

information regarding tires, refer to “Important Tire Safety In- formation” (US) or “Tire Safety Informa- tion” (Canada) in the Warranty Informa- tion Booklet.

All season tires NISSAN specifies All Season tires on some mod- els to provide good performance all year, includ- ing snowy and icy road conditions. All Season tires are identified by ALL SEASON and/or M&S on the tire sidewall. Snow tires have better snow traction than All Season tires and may be more appropriate in some areas.

Summer tires NISSAN specifies summer tires on some models to provide superior performance on dry roads. Summer tire performance is substantially re- duced in snow and ice. Summer tires do not have the tire traction rating “M&S” on the tire sidewall.

If you do not,

If you plan to operate your vehicle in snowy or icy conditions, NISSAN recommends the use of SNOW tires or ALL SEASON tires on all four wheels. Snow tires If snow tires are needed, it is necessary to select tires equivalent in size and load rating to the original equipment tires. it can adversely affect the safety and handling of your vehicle. Generally, snow tires have lower speed ratings than factory equipped tires and may not match the potential maximum vehicle speed. Never ex- ceed the maximum speed rating of the tire. If you install snow tires, they must be the same size, brand, construction and tread pattern on all four wheels. For additional traction on icy roads, studded tires may be used. However, some U.S. states and Canadian provinces prohibit their use. Check local, state and provincial laws before installing

Tire chains must be installed only on the rear wheels and not on the front wheels. Do not use tire chains on dry roads. Driving with chains in such conditions can cause damage to the various mechanisms of the vehicle due to some overstress. Use only the 2WD range when driving on clear paved roads.

studded tires. Skid and traction capabilities of studded snow tires on wet or dry surfaces may be poorer than that of non-studded snow tires. TIRE CHAINS Use of tire chains may be prohibited according to location. Check the local laws before installing tire chains. When installing tire chains, make sure they are the proper size for the tires on your vehicle and are installed according to the chain manufacturer’s suggestions. Use only SAE class “S” chains. Class “S” chains are used on vehicles with restricted tire to vehicle clearance. Vehicles that can use Class “S” chains are de- signed to meet the minimum clearances between the tire and the closest vehicle suspension or body component required to accommodate the use of a winter traction device (tire chains or cables). The minimum clearances are determined using the factory equipped tire size. Other types may damage your vehicle. Use chain tensioners when recommended by the tire chain manufac- turer to ensure a tight fit. Loose end links of the tire chain must be secured or removed to prevent the possibility of whipping action damage to the fenders or underbody. If possible, avoid fully load- ing your vehicle when using tire chains. In addi- tion, drive at a reduced speed. Otherwise, your vehicle may be damaged and/or vehicle handling and performance may be adversely affected.

WDI0258

CHANGING WHEELS AND TIRES Tire rotation NISSAN recommends rotating the tires every 7,500 miles (12,000 km). See “Flat tire” in the “In case of emer- gency” section in this manual for tire re- placing procedures. As soon as possible, tighten the wheel nuts to the specified torque with a torque wrench.

Maintenance and do-it-yourself 8-39

Wheel nut tightening torque:

98 ft-lb (133 N·m)

The wheel nuts must be kept tight- ened to specifications at all times. It is recommended that wheel nuts be tightened to specification at each tire rotation interval.

WARNING

● After rotating the tires, check and

adjust the tire pressure.

● Retighten the wheel nuts when the vehicle has been driven for 600 miles (1,000 km) (also in cases of a flat tire, etc.).

● Do not include the spare tire in

the tire rotation. ● For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Information” (Canada) in the Warranty Infor- mation Booklet.

Safety

8-40 Maintenance and do-it-yourself

● The original tires have built-in tread wear indicators. When the wear indicators are visible, the tire(s) should be replaced.

● Tires degrade with age and use. Have tires, including the spare, over 6 years old checked by a qualified because some tire damage may not be ob- vious. Replace the tires as neces- sary to prevent tire failure and possible personal injury.

technician

● Improper service of the spare tire may result in serious personal in- jury. If it is necessary to repair the spare tire, contact a NISSAN dealer.

● For additional

information re- garding tires, refer to “Important Tire Safety Information” (US) or “Tire Information” (Canada) in the Warranty Infor- mation Booklet.

Safety

WDI0259

1. Wear indicator 2. Location mark Tire wear and damage

WARNING

● Tires should be periodically in- spected for wear, cracking, bulg- ing or objects caught in the tread. If excessive wear, cracks, bulging or deep cuts are found, the tire(s) should be replaced.

Replacing wheels and tires When replacing a tire, use the same size, tread design, speed rating and load carrying capacity as originally equipped. Recommended types and sizes are shown in “Wheels and tires” in the “Technical and consumer information” section of this manual.

WARNING

● The use of tires other than those recom- mended or the mixed use of tires of different brands, construction (bias, bias-belted or radial), or tread patterns can adversely affect the ride, braking, handling, VDC system, ground clear- ance, body-to-tire clearance, tire chain clearance, speedometer calibration, headlight aim and bumper height. Some of these effects may lead to acci- dents and could result in serious per- sonal injury.

● If your vehicle was originally equipped with 4 tires that were the same size and you are only replacing 2 of the 4 tires, install the new tires on the rear axle. Placing new tires on the front axle may cause loss of vehicle control in some driving conditions and cause an acci-