- 2007 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2012 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2008 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2002 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2003 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2004 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2011 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2010 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2006 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2001 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2009 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- 2005 Ford F 350 Owners Manuals

- Ford F 350 Owners Manuals

- Download PDF Manual

-

193

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

When children should use booster seats Children need to use booster seats from the time they outgrow the toddler seat until they are big enough for the vehicle seat and lap/shoulder belt to fit properly. Generally this is when they weigh about 80 lb. (36 kg) (about 8 to 12 years old). Booster seats should be used until you can answer YES to ALL of these questions: • Can the child sit all the way back against the vehicle seat back with knees bent comfortably at the edge of the seat without slouching?

• Does the lap belt rest low across the hips? • Is the shoulder belt centered on the shoulder and chest? • Can the child stay seated like this for the whole trip? Types of booster seats There are two types of belt-positioning booster seats: • Those that are backless.

If your backless booster seat has a removable shield, remove the shield and use the lap/shoulder belt. If a seating position has a low seat back and no head restraint, a backless booster seat may place your child’s head (top of ear level) above the top of the seat. In this case, move the backless booster to another seating position with a higher seat back and lap/shoulder belts.

194

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

• Those with a high back.

If, with a backless booster seat, you cannot find a seating position that adequately supports your child’s head, a high back booster seat would be a better choice.

Either type can be used at any seating position equipped with lap/shoulder belts if your child is over 40 lb. (18 kg). Children and booster seats vary widely in size and shape. Choose a booster that keeps the lap belt low and snug across the hips, never up across the stomach, and lets you adjust the shoulder belt to cross the chest and rest snugly near the center of the shoulder. The drawings below compare the ideal fit (center) to a shoulder belt uncomfortably close to the neck and a shoulder belt that could slip off the shoulder.

If the booster seat slides on the vehicle seat, placing a rubberized mesh sold as shelf or carpet liner under the booster seat may improve this condition. The importance of shoulder belts Using a booster without a shoulder belt increases the risk of a child’s head hitting a hard surface in a collision. For this reason, you should never use a booster seat with a lap belt only. It is best to use a booster seat with lap/shoulder belts in the back seat- the safest place for children to ride.

Move a child to a different seating location if the shoulder belt does not stay positioned on the shoulder during use.

195

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

Follow all instructions provided by the manufacturer of the booster seat.

Never put the shoulder belt under a child’s arm or behind the back because it eliminates the protection for the upper part of

the body and may increase the risk of injury or death in a collision.

Never use pillows, books, or towels to boost a child. They can slide around and increase the likelihood of injury or death in a

collision.

SAFETY SEATS FOR CHILDREN Child and infant or child safety seats Use a safety seat that is recommended for the size and weight of the child. Carefully follow all of the manufacturer’s instructions with the safety seat you put in your vehicle. If you do not install and use the safety seat properly, the child may be injured in a sudden stop or collision. When installing a child safety seat: • Review and follow the information

presented in the Airbag supplemental restraint system (SRS) section in this chapter. • Use the correct safety belt buckle for that seating position (the buckle closest to the direction the tongue is coming from).

• Insert the belt tongue into the proper buckle until you hear a snap and feel it latch. Make sure the tongue is securely fastened in the buckle. • Keep the buckle release button pointing up and away from the safety seat, with the tongue between the child seat and the release button, to prevent accidental unbuckling. • Place seat back in upright position. • Put the safety belt in the automatic locking mode. Refer to Automatic

locking mode (passenger side front and outboard rear seating positions) (if equipped) section in this chapter.

196

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints • Top tether anchors can be used for children up to 60 pounds (27 kg) in a child restraint, and to provide upper torso restraint for children up to 80 pounds (36 kg) using an upper torso harness and a belt-positioning booster.

Ford recommends the use of a child safety seat having a top tether strap. Install the child safety seat in a seating position with a tether anchor. For more information on top tether straps and anchors, refer to Attaching child safety seats with tether straps in this chapter.

Carefully follow all of the manufacturer’s instructions included with the safety seat you put in your vehicle. If you do not install and use the safety seat properly, the child may be injured in a sudden stop or collision.

Rear-facing child seats or infant carriers should never be placed in the front seats, unless the passenger airbag On/Off switch is

turned off. See Passenger airbag ON/OFF switch in this chapter.

Installing child safety seats with combination lap and shoulder belts 1. Position the child safety seat in a seat with a combination lap and shoulder belt.

An airbag can kill or injure a child in a child seat. Child seats should NEVER be placed in the front seats, unless the passenger

airbag switch is turned off, See Passenger airbag on/off switch.

Rear facing child seats should NEVER be placed in the front seats unless the passenger airbag switch is turned off.

197

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

2. Pull down on the shoulder belt and then grasp the shoulder belt and lap belt together.

3. While holding the shoulder and lap belt portions together, route the tongue through the child seat according to the child seat manufacturer’s instructions. Be sure the belt webbing is not twisted.

4. Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) for that seating position until you hear and feel the latch engage. Make sure the tongue is latched securely by pulling on it.

198

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

5. To put the retractor in the automatic locking mode, grasp the shoulder portion of the belt and pull downward until all of the belt is extracted and a click is heard.

6. Allow the belt to retract. The belt will click as it retracts to indicate it is in the automatic locking mode. 7. Pull the lap belt portion across the child seat toward the buckle and pull up on the shoulder belt while pushing down with knee on the child seat.

8. Allow the safety belt to retract to remove any slack in the belt. 9. Before placing the child in the seat, forcibly tilt the seat forward and back to make sure the seat is securely held in place. To check this, grab the seat at the belt path and attempt to move it side to side and forward. There should be no more than one inch of movement for proper installation. 10. Try to pull the belt out of the retractor to make sure the retractor is in the automatic locking mode (you should not be able to pull more belt out). If the retractor is not locked, unbuckle the belt and repeat Steps two through nine. Check to make sure the child seat is properly secured before each use.

199

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

Attaching child safety seats with tether straps Most new forward-facing child safety seats include a tether strap which goes over the back of the seat and hooks to an anchoring point. Tether straps are available as an accessory for many older safety seats. Contact the manufacturer of your child seat for information about ordering a tether strap. The passenger seats of your vehicle may be equipped with built-in tether strap anchors located behind the seats as described below. The tether anchors in your vehicle may be straps on the seatback or an anchor bracket on the rear edge of the seat cushion or an anchor bracket mounted to the body shell on the back panel. The SuperCab rear seat has three straps behind the top of the seat back that function as both routing loops for the tether straps and anchor loops. The tether strap anchors in your vehicle are in the following positions (shown from top view):

Attach the tether strap only to the appropriate tether anchor as shown. The tether strap may not work properly if attached

somewhere other than the correct tether anchor. • F-Series Regular Cab

• F-Series SuperCab

200

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

• F-Series Crew Cab

Seating and Safety Restraints

Tether strap attachment 1. Position the child safety seat on the seat cushion. 2. Route the child safety seat tether strap over the back of the seat. 3. Locate the correct anchor for the selected seating position. 4. You may need to pull the seatback forward to access the tether anchors. Make sure the seat is locked in the upright position before installing the child seat. Refer to the Rear folding seat system with load floor section in this chapter for information on how to operate the rear seats. 5. Remove tether cover.

6. Clip the tether strap to the anchor as shown. • Front seats (Regular Cab)

201

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints • Front seat (SuperCab)

• Rear seats (Crew Cab)

If the tether strap is clipped incorrectly, the child safety seat may not be retained properly in the event of a collision.

7. Refer to the Installing child safety seats with combination lap and shoulder belts section of this chapter for further instructions to secure the child safety seat. 8. Tighten the child safety seat tether strap according to the manufacturer’s instructions.

If the safety seat is not anchored properly, the risk of a child being injured in a collision greatly increases.

Tether strap attachment (rear SuperCab only) There are three loops of webbing just above the back of the rear seat (along the bottom edge of the rear window) in the SuperCab. These loops are to be used as both routing loops and anchor loops for up to three child safety seat tether straps. These straps may be secured below the back of the seat with rubber bands. To access, reach below the back of the seat and pull tether loop out of the rubber band securing it.

202

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Seating and Safety Restraints

Many tether straps cannot be tightened if the tether strap is hooked to the loop directly behind the child seat. To provide a tight tether strap: 1. Route the tether strap through the loop directly behind the child seat.

2. Attach the strap hook onto the loop behind an adjacent seating position.

3. Install the child safety seat tightly using the vehicle belts. Follow the instructions in this chapter. 4. Tighten the tether strap according to the child seat manufacturer’s instructions.

A single loop can be used to route and anchor more than one child seat. For example, the center loop can be used as a routing loop for a child safety seat in the center rear seat and as an anchoring loop for child seats installed in the outboard rear seats.

203

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

NOTICE TO UTILITY VEHICLE AND TRUCK OWNERS Utility vehicles and trucks handle differently than passenger cars in the various driving conditions that are encountered on streets, highways and off-road. Utility vehicles and trucks are not designed for cornering at speeds as high as passenger cars any more than low-slung sports cars are designed to perform satisfactorily under off-road conditions.

Utility vehicles have a significantly higher rollover rate than other types of vehicles. To reduce the risk of serious injury or

death from a rollover or other crash you must: • Avoid sharp turns and abrupt maneuvers; • Drive at safe speeds for the conditions; • Keep tires properly inflated; • Never overload or improperly load your vehicle; and • Make sure every passenger is properly restrained.

In a rollover crash, an unbelted person is significantly more likely to die than a person wearing a seat belt. All occupants must

wear safety belts and children/infants must use appropriate restraints to minimize the risk of injury or ejection.

Study your Owner’s Guide and any supplements for specific information about equipment features, instructions for safe driving and additional precautions to reduce the risk of an accident or serious injury.

VEHICLE CHARACTERISTICS

4WD and AWD Systems (if equipped) A vehicle equipped with AWD or 4WD (when you select the 4WD mode) has the ability to use all four wheels to power itself. This increases traction which may enable you to safely drive over terrain and road conditions that a conventional two-wheel drive vehicle cannot.

204

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Power is supplied to all four wheels through a transfer case or power transfer unit. 4WD vehicles allow you to select different drive modes as necessary. Information on shifting procedures and maintenance can be found in your Owner’s Guide. You should become thoroughly familiar with this information before you operate your vehicle. On some 4WD models, the initial shift from two-wheel drive to 4WD while the vehicle is moving can cause a momentary clunk and ratcheting sound. These sounds are normal as the front drivetrain comes up to speed and is not cause for concern.

Do not become overconfident in the ability of 4WD and AWD vehicles. Although a 4WD or AWD vehicle may accelerate better

than two-wheel drive vehicle in low traction situations, it won’t stop any faster than two-wheel drive vehicles. Always drive at a safe speed.

How your vehicle differs from other vehicles SUV and trucks can differ from some other vehicles in a few noticeable ways. Your vehicle may be: • Higher – to allow higher load carrying capacity and to allow it to travel over rough terrain without getting hung up or damaging underbody components. • Shorter – to give it the capability

to approach inclines and drive over the crest of a hill without getting hung up or damaging underbody components. All other things held equal, a shorter wheelbase may make your vehicle quicker to respond to steering inputs than a vehicle with a longer wheelbase.

205

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading • Narrower — to provide greater maneuverability in tight spaces, particularly in off-road use.

As a result of the above dimensional differences, SUV’s and trucks often will have a higher center of gravity and a greater difference in center of gravity between the loaded and unloaded condition. These differences that make your vehicle so versatile also make it handle differently than an ordinary passenger car.

INFORMATION ABOUT UNIFORM TIRE QUALITY GRADING Tire Quality Grades apply to new pneumatic passenger car tires. The Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example: • Treadwear 200 Traction AA Temperature A These Tire Quality Grades are determined by standards that the United States Department of Transportation has set. Tire Quality Grades apply to new pneumatic passenger car tires. They do not apply to deep tread, winter-type snow tires, space-saver or temporary use spare tires, light truck or “LT” type tires, tires with nominal rim diameters of 10 to 12 inches or limited production tires as defined in Title 49 Code of Federal Regulations Part 575.104(c)(2). U.S. Department of Transportation-Tire quality grades: The U.S. Department of Transportation requires Ford Motor Company to give you the following information about tire grades exactly as the government has written it.

206

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Treadwear The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and one-half (1 1/2) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices, and differences in road characteristics and climate.

Traction AA A B C The traction grades, from highest to lowest are AA, A, B, and C. The grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

The traction grade assigned to this tire is based on straight-ahead braking traction tests, and does not include

acceleration, cornering, hydroplaning or peak traction characteristics.

Temperature A B C The temperature grades are A (the highest), B and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 139. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law.

The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed,

underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

207

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

TIRES Tires are designed to give many thousands of miles of service, but they must be maintained in order to get the maximum benefit from them.

Glossary of tire terminology • Tire Label: A label showing the OE (Original Equipment) tire sizes, recommended inflation pressure and the maximum weight the vehicle can carry.

• Tire Identification Number (TIN): A number on the sidewall of each tire providing information about the tire brand and manufacturing plant, tire size and date of manufacture. Also referred to as DOT code.

• Inflation pressure: A measure of the amount of air in a tire. • Standard load: A class of P-metric or Metric tires designed to carry a maximum load at 35 psi [37 psi (2.5 bar) for Metric tires]. Increasing the inflation pressure beyond this pressure will not increase the tire’s load carrying capability.

• Extra load: A class of P-metric or Metric tires designed to carry a heavier maximum load at 41 psi [43 psi (2.9 bar) for Metric tires]. Increasing the inflation pressure beyond this pressure will not increase the tire’s load carrying capability.

• kPa: Kilopascal, a metric unit of air pressure. • PSI: Pounds per square inch, a standard unit of air pressure. • Cold inflation pressure: The tire pressure when the vehicle has been stationary and out of direct sunlight for an hour or more and prior to the vehicle being driven for 1 mile (1.6 km).

front door.

• Recommended inflation pressure: The cold inflation pressure found on the Tire Label or Safety Compliance Certification Label located on the B-Pillar or the edge of the driver’s door. • B-pillar: The structural member at the side of the vehicle behind the • Bead area of the tire: Area of the tire next to the rim. • Sidewall of the tire: Area between the bead area and the tread. • Tread area of the tire: Area of the perimeter of the tire that • Rim: The metal support (wheel) for a tire or a tire and tube assembly

contacts the road when mounted on the vehicle.

upon which the tire beads are seated.

208

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

INFLATING YOUR TIRES Safe operation of your vehicle requires that your tires are properly inflated. Remember that a tire can lose up to half of its air pressure without appearing flat. Every day before you drive, check your tires. If one looks lower than the others, use a tire gauge to check pressure of all tires and adjust if required. At least once a month and before long trips, inspect each tire and check the tire pressure with a tire gauge (including spare, if equipped). Inflate all tires to the inflation pressure recommended by Ford Motor Company. Use a tire gauge to check the tire inflation pressure, including the spare (if equipped), at least monthly and before long trips. You are strongly urged to buy a reliable tire pressure gauge, as automatic service station gauges may be inaccurate. Ford recommends the use of a digital or dial-type tire pressure gauge rather than a stick-type tire pressure gauge. Use the recommended cold inflation pressure for optimum tire performance and wear. Under-inflation or over-inflation may cause uneven treadwear patterns.

Under-inflation is the most common cause of tire failures and may result in severe tire cracking, tread separation or ⬙blowout⬙,

with unexpected loss of vehicle control and increased risk of injury. Under-inflation increases sidewall flexing and rolling resistance, resulting in heat buildup and internal damage to the tire. It also may result in unnecessary tire stress, irregular wear, loss of vehicle control and accidents. A tire can lose up to half of its air pressure and not appear to be flat!

Always inflate your tires to the Ford recommended inflation pressure even if it is less than the maximum inflation pressure information found on the tire. The Ford recommended tire inflation pressure is found on the Safety Compliance Certification Label or Tire Label which is located on the B-Pillar or the edge of the driver’s door. Failure to follow the tire pressure recommendations can cause uneven treadwear patterns and adversely affect the way your vehicle handles. Maximum Permissible Inflation Pressure is the tire manufacturer’s maximum permissible pressure and/or the pressure at which the maximum load can be carried by the tire. This pressure is normally higher than the manufacturer’s recommended cold inflation pressure which can be found on the Safety Compliance Certification Label or Tire

209

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Label which is located on the B-Pillar or the edge of the driver’s door. The cold inflation pressure should never be set lower than the recommended pressure on the Safety Compliance Certification Label or Tire Label. When weather temperature changes occur, tire inflation pressures also change. A 10°F (6°C) temperature drop can cause a corresponding drop of 1 psi (7 kPa) in inflation pressure. Check your tire pressures frequently and adjust them to the proper pressure which can be found on the Safety Compliance Certification Label or the Tire Label. To check the pressure in your tire(s): 1. Make sure the tires are cool, meaning they are not hot from driving even a mile. If you are checking tire pressure when the tire is hot, (i.e. driven more than 1 mile [1.6 km]), never “bleed” or reduce air pressure. The tires are hot from driving and it is normal for pressures to increase above recommended cold pressures. A hot tire at or below recommended cold inflation pressure could be significantly under-inflated. Note: If you have to drive a distance to get air for your tire(s), check and record the tire pressure first and add the appropriate air pressure when you get to the pump. It is normal for tires to heat up and the air pressure inside to go up as you drive. 2. Remove the cap from the valve on one tire, then firmly press the tire gauge onto the valve and measure the pressure with the tire gauge. 3. Add enough air to reach the recommended air pressure Note: If you overfill the tire, release air by pushing on the metal stem in the center of the valve. Then recheck the pressure with your tire gauge. 4. Replace the valve cap. 5. Repeat this procedure for each tire, including the spare. Note: Some spare tires operate at a higher inflation pressure than the other tires. For T-type/mini-spare tires (see Dissimilar Spare Tire/Wheel Information section for description): Store and maintain at 60 psi (4.15

bar). For dissimilar spare tires and full-size matching spare tires (see the Dissimilar Spare Tire/Wheel Information and Full-size Matching Spare Tire/Wheel Information sections for descriptions): Store and maintain at the higher of the front and rear inflation pressure as shown on the or Safety Compliance Certification Label or the Tire Label. 6. Visually inspect the tires to make sure there are no nails or other objects embedded that could poke a hole in the tire and cause an air leak. 7. Check the sidewalls to make sure there are no gouges, cuts or bulges.210

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Tire inflation information All tires with Steel Carcass Plies (if equipped): This type of tire utilizes steel cords in the sidewalls. As such, they cannot be treated like normal light truck tires. Tire service, including adjusting the air pressure, must be performed by personnel trained, supervised and equipped according to Federal Occupational Safety and Health Administration (OSHA) regulations. For example, during any procedure involving tire inflation, the technician or individual must utilize a remote inflation device, and ensure that all persons are clear of the trajectory area.

WARNING An inflated tire and rim can be very dangerous if improperly used, serviced or maintained. To avoid serious injury,

never attempt to re-inflate a tire which has been run flat or seriously under-inflated without first removing the tire from the wheel assembly for inspection. Do not attempt to add air to tires or replace tires or wheels without first taking precautions to protect persons and property.

211

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Stay out of the trajectory (1) as indicated in the illustration.

TIRE CARE

Inspecting your tires Periodically inspect the tire treads for uneven or excessive wear and remove objects such as stones, nails or glass that may be wedged in the tread grooves. Check for holes or cuts that may permit air leakage from the tire and make necessary repairs. Also inspect the tire sidewalls for cracking, cuts, bruises and other signs of damage or excessive wear. If internal damage to the tire is suspected, have the tire demounted and inspected in case it needs to be repaired or replaced. For your safety, tires that are damaged or show signs of excessive wear should not be used because they are more likely to blow out or fail. Improper or inadequate vehicle maintenance can cause tires to wear abnormally. Inspect all your tires, including the spare, frequently, and replace them if one or more of the following conditions exist:

212

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Tire wear When the tread is worn down to 1/16th of an inch (2 mm), tires must be replaced to help prevent your vehicle from skidding and hydroplaning. Built-in treadwear indicators, or “wear bars”, which look like narrow strips of smooth rubber across the tread will appear on the tire when the tread is worn down to 1/16th of an inch (2 mm). When the tire tread wears down to the same height as these “wear bars”, the tire is worn out and must be replaced.

Damage Periodically inspect the tire treads and sidewalls for damage (such as bulges in the tread or sidewalls, cracks in the tread groove and separation in the tread or sidewall). If damage is observed or suspected have the tire inspected by a tire professional. Tires can be damaged during off-road use, so inspection after off-road use is also recommended.

Age Tires degrade over time depending on many factors such as

weather, storage conditions, and conditions of use (load, speed, inflation pressure, etc.) the tires experience throughout their lives. In general, tires should be replaced after 6 years regardless of tread wear. However, heat caused by hot climates or frequent high loading conditions can accelerate the aging process and may require tires to be replaced more frequently. You should replace your spare tire when you replace the road tires or after 6 years due to aging even if it has not been used.

213

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

U.S. DOT Tire Identification Number (TIN) U.S. and Canada Federal regulations require tire manufacturers to place standardized information on the sidewall of all tires. This information identifies and describes the fundamental characteristics of the tire and also provides a U.S. DOT Tire Identification Number for safety standard certification and in case of a recall. This begins with the letters “DOT” and indicates that the tire meets all federal standards. The next two numbers or letters are the plant code designating where it was manufactured, the next two are the tire size code and the last four numbers represent the week and year the tire was built. For example, the numbers 317 mean the 31st week of 1997. After 2000 the numbers go to four digits. For example, 2501 means the 25th week of 2001. The numbers in between are identification codes used for traceability. This information is used to contact customers if a tire defect requires a recall.

Tire replacement requirements Your vehicle is equipped with tires designed to provide a safe ride and handling capability.

Only use replacement tires and wheels that are the same size, load index, speed rating and type (such as P-metric versus

LT-metric or all-season versus all-terrain) as those originally provided by Ford. The recommended tire and wheel size may be found on either the Safety Compliance Certification Label or the Tire Label which is located on the B-Pillar or edge of the driver’s door. If this information is not found on these labels then you should consult your Ford Dealer. Use of any tire or wheel not recommended by Ford can affect the safety and performance of your vehicle, which could result in an increased risk of loss of vehicle control, vehicle rollover, personal injury and death. Additionally the use of non-recommended tires and wheels could cause steering, suspension, axle or transfer case/power transfer unit failure. If you have questions regarding tire replacement, see an authorized dealer.

214

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

When mounting replacement tires and wheels, you should not exceed the maximum pressure indicated on the sidewall of the

tire to set the beads without additional precautions listed below. If the beads do not seat at the maximum pressure indicated, re-lubricate and try again. When inflating the tire for mounting pressures up to 20 psi (138 kPa) greater than the maximum pressure on the tire sidewall, the following precautions must be taken to protect the person mounting the tire: 1. Make sure you have the correct tire and wheel size 2. Lubricate the tire bead and wheel bead area again 3. Stand at a minimum of 12 ft. (3.7 m) away from the tire wheel assembly 4. Use both eye and ear protection For a mounting pressure more than 20 psi (138 kPa) greater than the maximum pressure, a Ford Dealer or other tire service professional should do the mounting. Always inflate steel carcass tires with a remote air fill with the person inflating standing at a minimum of 12 ft. (3.7 m) away from the tire wheel assembly.

Important: Remember to replace the wheel valve stems when the road tires are replaced on your vehicle. It is recommended that the two front tires or two rear tires generally be replaced as a pair. The tire pressure sensors mounted in the wheels (if equipped) are not designed to be used in aftermarket wheels. The use of wheels or tires not recommended by Ford Motor Company may affect the operation of your Tire Pressure Monitoring System (if equipped). If the TPMS indicator is flashing, your TPMS is malfunctioning. Your replacement tire might be incompatible with your TPMS, or some component of the TPMS may be damaged (if equipped).

Safety practices Driving habits have a great deal to do with your tire mileage and safety. • Observe posted speed limits • Avoid fast starts, stops and turns • Avoid potholes and objects on the road

215

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading • Do not run over curbs or hit the tire against a curb when parking

If your vehicle is stuck in snow, mud, sand, etc., do not rapidly spin the tires; spinning the tires can tear the tire and cause an

explosion. A tire can explode in as little as three to five seconds.

Never spin the tires in excess of the 35 mph (55 km/h) point indicated on the speedometer.

Highway hazards No matter how carefully you drive there’s always the possibility that you may eventually have a flat tire on the highway. Drive slowly to the closest safe area out of traffic. This may further damage the flat tire, but your safety is more important. If you feel a sudden vibration or ride disturbance while driving, or you suspect your tire or vehicle has been damaged, immediately reduce your speed. Drive with caution until you can safely pull off the road. Stop and inspect the tires for damage. If a tire is under-inflated or damaged, deflate it, remove wheel and replace it with your spare tire and wheel. If you cannot detect a cause, have the vehicle towed to the nearest repair facility or tire dealer to have the vehicle inspected.

Tire and wheel alignment A bad jolt from hitting a curb or pothole can cause the front end of your vehicle to become misaligned or cause damage to your tires. If your vehicle seems to pull to one side when you’re driving, the wheels may be out of alignment. Have your authorized dealer check the wheel alignment periodically. Wheel misalignment in the front or the rear can cause uneven and rapid treadwear of your tires and should be corrected by your authorized dealer. Front Wheel Drive (FWD) vehicles and those with an independent rear suspension (if equipped) may require alignment of all four wheels. The tires should also be balanced periodically. An unbalanced tire and wheel assembly may result in irregular tire wear.

216

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Tire rotation Rotating your tires at the recommended interval (as indicated in the scheduled maintenance information that comes with your vehicle) will help your tires wear more evenly, providing better tire performance and longer tire life. • Rear Wheel Drive (RWD)

vehicles/Four Wheel Drive (4WD) (front tires at top of diagram)

Sometimes irregular tire wear can be corrected by rotating the tires. Note: If your tires show uneven wear ask your authorized dealer to check for and correct any wheel misalignment, tire imbalance or mechanical problem involved before tire rotation. Note: Your vehicle may be equipped with a dissimilar spare tire/wheel. A dissimilar spare tire/wheel is defined as a spare tire and/or wheel that is different in brand, size or appearance from the road tires and wheels. If you have a dissimilar spare tire/wheel it is intended for temporary use only and should not be used in a tire rotation. Note: After having your tires rotated, inflation pressure must be checked and adjusted to the vehicle requirements.

217

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading • Dual Rear Wheel (DRW) – Six

tire rotation

If your vehicle is equipped with dual rear wheels it is recommended that the front and rear tires (in pairs) be rotated only side to side. We do not recommend splitting up the dual rear wheels. Rotate them side to side as a set/pair. After tire rotation, inflation pressures must be adjusted for the tires new positions in accordance with vehicle requirements.

Sometimes irregular tire wear can be corrected by rotating the tires. Note: If your tires show uneven wear ask your authorized dealer to check for and correct any wheel misalignment, tire imbalance or mechanical problem involved before tire rotation. Note: Your vehicle may be equipped with a dissimilar spare tire/wheel. A dissimilar spare tire/wheel is defined as a spare tire and/or wheel that is different in brand, size or appearance from the road tires and wheels. If you have a dissimilar spare tire/wheel it is intended for temporary use only and should not be used in a tire rotation. Note: After having your tires rotated, inflation pressure must be checked and adjusted to the vehicle requirements.

If the tire label shows different tire pressures for the front and rear tires and the vehicle is equipped with TPMS (tire pressure

monitoring system), then the settings for the TPMS sensors need to be updated. Always perform the TPMS reset procedure after tire rotation. If the system is not reset, it may not provide a low tire pressure warning when necessary. See the TPMS reset procedure in this chapter.

218

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

INFORMATION CONTAINED ON THE TIRE SIDEWALL U.S. and Canada Federal regulations require tire manufacturers to place standardized information on the sidewall of all tires. This information identifies and describes the fundamental characteristics of the tire and also provides a U.S. DOT Tire Identification Number for safety standard certification and in case of a recall.

Information on “P” type tires P215/65R15 95H is an example of a tire size, load index and speed rating. The definitions of these items are listed below. (Note that the tire size, load index and speed rating for your vehicle may be different from this example.) 1. P: Indicates a tire, designated by the Tire and Rim Association (T&RA), that may be used for service on cars, SUVs, minivans and light trucks. Note: If your tire size does not begin with a letter this may mean it is designated by either ETRTO (European Tire and Rim Technical Organization) or JATMA (Japan Tire Manufacturing Association). 2. 215: Indicates the nominal width of the tire in millimeters from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire. 3. 65: Indicates the aspect ratio which gives the tire’s ratio of height to width. 4. R: Indicates a “radial” type tire. 5. 15: Indicates the wheel or rim diameter in inches. If you change your wheel size, you will have to purchase new tires to match the new wheel diameter. 6. 95: Indicates the tire’s load index. It is an index that relates to how much weight a tire can carry. You may find this information in your Owner’s Guide. If not, contact a local tire dealer. Note: You may not find this information on all tires because it is not required by federal law.

219

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

7. H: Indicates the tire’s speed rating. The speed rating denotes the speed at which a tire is designed to be driven for extended periods of time under a standard condition of load and inflation pressure. The tires on your vehicle may operate at different conditions for load and inflation pressure. These speed ratings may need to be adjusted for the difference in conditions. The ratings range from 81 mph (130 km/h) to 186 mph (299 km/h). These ratings are listed in the following chart. Note: You may not find this information on all tires because it is not required by federal law.

Letter rating

Speed rating - mph (km/h)

81 mph (130 km/h) 87 mph (140 km/h) 99 mph (159 km/h) 106 mph (171 km/h) 112 mph (180 km/h) 118 mph (190 km/h) 124 mph (200 km/h) 130 mph (210 km/h) 149 mph (240 km/h) 168 mph (270 km/h) 186 mph (299 km/h)

Note: For tires with a maximum speed capability over 149 mph (240

km/h), tire manufacturers sometimes use the letters ZR. For those with a maximum speed capability over 186 mph (299 km/h), tire manufacturers always use the letters ZR. 8. U.S. DOT Tire Identification Number (TIN): This begins with the letters “DOT” and indicates that the tire meets all federal standards. The next two numbers or letters are the plant code designating where it was manufactured, the next two are the tire size code and the last four numbers represent the week and year the tire was built. For example, the numbers 317 mean the 31st week of 1997. After 2000 the numbers go to four digits. For example, 2501 means the 25th week of 2001. The numbers in between are identification codes used for traceability. This information is used to contact customers if a tire defect requires a recall. 9. M+S or M/S: Mud and Snow, or AT: All Terrain, or AS: All Season.220

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

10. Tire Ply Composition and Material Used: Indicates the number of plies or the number of layers of rubber-coated fabric in the tire tread and sidewall. Tire manufacturers also must indicate the ply materials in the tire and the sidewall, which include steel, nylon, polyester, and others. 11. Maximum Load: Indicates the maximum load in kilograms and pounds that can be carried by the tire. Refer to the Tire Label or Safety Compliance Certification Label, which is located on the B-Pillar or the edge of the driver’s door, for the correct tire pressure for your vehicle. 12. Treadwear, Traction and Temperature Grades • Treadwear: The treadwear grade is a comparative rating based on the

wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150

would wear one and one-half (11⁄2) times as well on the government course as a tire graded 100. • Traction: The traction grades, from highest to lowest are AA, A, B,and C. The grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

• Temperature: The temperature grades are A (the highest), B and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel.

13. Maximum Permissible Inflation Pressure: Indicates the tire manufacturers’ maximum permissible pressure and/or the pressure at which the maximum load can be carried by the tire. This pressure is normally higher than the manufacturer’s recommended cold inflation pressure which can be found on either the Tire Label or Safety Compliance Certification Label which is located on the B-Pillar or the edge of the driver’s door. The cold inflation pressure should never be set lower than the recommended pressure on the vehicle label. The tire suppliers may have additional markings, notes or warnings such as standard load, radial tubeless, etc.

221

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Additional information contained on the tire sidewall for “LT” type tires “LT” type tires have some additional information beyond those of “P” type tires; these differences are described below. Note: Tire Quality Grades do not apply to this type of tire. 1. LT: Indicates a tire, designated by the Tire and Rim Association (T&RA), that is intended for service on light trucks. 2. Load Range/Load Inflation Limits: Indicates the tire’s load-carrying capabilities and its inflation limits. 3. Maximum Load Dual lb. (kg) at psi (kPa) cold: Indicates the maximum load and tire pressure when the tire is used as a dual; defined as four tires on the rear axle (a total of six or more tires on the vehicle). 4. Maximum Load Single lb. (kg) at psi (kPa) cold: Indicates the maximum load and tire pressure when the tire is used as a single; defined as two tires (total) on the rear axle.

222

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Information on “T” type tires “T” type tires have some additional information beyond those of “P” type tires; these differences are described below: T145/80D16 is an example of a tire size. Note: The temporary tire size for your vehicle may be different from this example. Tire Quality Grades do not apply to this type of tire. 1. T: Indicates a type of tire, designated by the Tire and Rim Association (T&RA), that is intended for temporary service on cars, SUVs, minivans and light trucks. 2. 145: Indicates the nominal width of the tire in millimeters from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire. 3. 80: Indicates the aspect ratio which gives the tire’s ratio of height to width. Numbers of 70 or lower indicate a short sidewall. 4. D: Indicates a “diagonal” type tire. R: Indicates a “radial” type tire. 5. 16: Indicates the wheel or rim diameter in inches. If you change your wheel size, you will have to purchase new tires to match the new wheel diameter.

Location of the Tire Label or Safety Compliance Certification Label You will find a Tire Label or Safety Compliance Certification Label containing tire inflation pressure by tire size and other important information located on the B-Pillar or the edge of the driver’s door. Refer to the payload description and graphic in the Vehicle loading — with and without a trailer section.

223

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

TIRE PRESSURE MONITORING SYSTEM (TPMS) (IF EQUIPPED) Each tire, including the spare (if provided), should be checked monthly when cold and inflated to the inflation pressure recommended by the vehicle manufacturer on the vehicle placard or tire inflation pressure label. (If your vehicle has tires of a different size than the size indicated on the vehicle placard or tire inflation pressure label, you should determine the proper tire inflation pressure for those tires.) As an added safety feature, your vehicle has been equipped with a tire pressure monitoring system (TPMS) that illuminates a low tire pressure telltale when one or more of your tires is significantly under-inflated. Accordingly, when the low tire pressure telltale illuminates, you should stop and check your tires as soon as possible, and inflate them to the proper pressure. Driving on a significantly under-inflated tire causes the tire to overheat and can lead to tire failure. Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle’s handling and stopping ability. Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s responsibility to maintain correct tire pressure, even if under-inflation has not reached the level to trigger illumination of the TPMS low tire pressure telltale. Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the system is not operating properly. The TPMS malfunction indicator is combined with the low tire pressure telltale. When the system detects a malfunction, the telltale will flash for approximately one minute and then remain continuously illuminated. This sequence will continue upon subsequent vehicle start-ups as long as the malfunction exists. When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may occur for a variety of reasons, including the installation of replacement or alternate tires or wheels on the vehicle that prevent the TPMS from functioning properly. Always check the TPMS malfunction telltale after replacing one or more tires or wheels on your vehicle to ensure that the replacement or alternate tires and wheels allow the TPMS to continue to function properly.

224

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

The Tire Pressure Monitoring System complies with part 15 of the FCC rules and with RSS-210 of Industry Canada. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause undesired operation.

The Tire Pressure Monitoring System is NOT a substitute for manually checking tire pressure. The tire pressure should be

checked periodically (at least monthly) using a tire gauge, see Inflating your tires in this chapter. Failure to properly maintain your tire pressure could increase the risk of tire failure, loss of control, vehicle rollover and personal injury.

Changing tires with TPMS Each road tire is equipped with a tire pressure sensor fastened to the inside rim of the wheel. The pressure sensor is covered by the tire and is not visible unless the tire is removed. The pressure sensor is located opposite (180 degrees) from the valve stem. Care must be taken when changing the tire to avoid damaging the sensor. It is recommended that you always have your tires serviced by an authorized dealer. The tire pressure should be checked periodically (at least monthly) using an accurate tire gauge, refer to Inflating your tires in this chapter.

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

225

Tires, Wheels and Loading

Understanding your Tire Pressure Monitoring System (TPMS) The Tire Pressure Monitoring System measures pressure in your four road tires and sends the tire pressure readings to your vehicle. The Low Tire Warning Lamp will turn ON if the tire pressure is significantly low. Once the light is illuminated, your tires are under inflated and need to be inflated to the manufacturer’s recommended tire pressure. Even if the light turns ON and a short time later turns OFF, your tire pressure still needs to be checked. Visit www.checkmytires.org for additional information. When your temporary spare tire is installed When one of your road tires needs to be replaced with the temporary spare, the TPMS system will continue to identify an issue to remind you that the damaged road wheel/tire needs to be repaired and put back on your vehicle. To restore the full functionality of the Tire Pressure Monitoring System, have the damaged road wheel/tire repaired and remounted on your vehicle. For additional information, refer to Changing tires with TPMS in this section.

226

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

When you believe your system is not operating properly The main function of the Tire Pressure Monitoring System is to warn you when your tires need air. It can also warn you in the event the system is no longer capable of functioning as intended. Please refer to the following chart for information concerning your Tire Pressure Monitoring System:

Possible cause Customer Action Required

Low Tire Pressure Warning Light Solid Warning Light Tire(s)

under-inflated

1. Check your tire pressure to ensure tires are properly inflated; refer to Inflating your tires in this chapter. 2. After inflating your tires to the manufacturer’s recommended inflation pressure as shown on the Tire Label (located on the edge of driver’s door or the B-Pillar), the vehicle must be driven for at least two minutes over 20 mph (32 km/h) before the light will turn OFF. Your temporary spare tire is in use. Repair the damaged road wheel/tire and reinstall it on the vehicle to restore system functionality. For a description on how the system functions, refer to When your temporary spare tire is installed in this section. If your tires are properly inflated and your spare tire is not in use and the light remains ON, have the system inspected by your authorized dealer. On vehicles with different front and rear tire pressures, the TPMS system must be retrained following every tire rotation. Refer to Tire rotation in this chapter.

227

Spare tire in use

TPMS malfunction

Tire rotation without sensor training

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Low Tire Pressure Warning Light Flashing Warning Light

Possible cause Customer Action Required

Spare tire in use

TPMS malfunction

Your temporary spare tire is in use. Repair the damaged road wheel and re-mount it on the vehicle to restore system functionality. For a description of how the system functions under these conditions, refer to When your temporary spare tire is installed in this section. If your tires are properly inflated and your spare tire is not in use and the TPMS warning light still flashes, have the system inspected by your authorized dealer.

When inflating your tires When putting air into your tires (such as at a gas station or in your garage), the Tire Pressure Monitoring System may not respond immediately to the air added to your tires. It may take up to two minutes of driving over 20 mph (32 km/h) for the light to turn OFF after you have filled your tires to the recommended inflation pressure. How temperature affects your tire pressure The Tire Pressure Monitoring System (TPMS) monitors tire pressure in each pneumatic tire. While driving in a normal manner, a typical passenger tire inflation pressure may increase approximately 2 to 4 psi (14 to 28 kPa) from a cold start situation. If the vehicle is stationary over night with the outside temperature significantly lower than the daytime temperature, the tire pressure may decrease approximately 3 psi (20.7 kPa) for a drop of 30° F (16.6°C) in ambient temperature. This lower pressure value may be detected by the TPMS as being significantly lower than the recommended inflation pressure and activate the TPMS warning for low tire pressure. If the low tire pressure warning light is ON, visually check each tire to verify that no tire is flat. (If one or more tires are flat, repair as necessary.) Check air pressure in the road tires. If any tire is under-inflated, carefully drive the vehicle to the nearest location where air can be added to the tires. Inflate all the tires to the recommended inflation pressure.

228

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

TPMS reset procedure (if applicable) This procedure is only required after tire rotation on vehicles with different front and rear tire pressures.

To determine if your vehicle requires two different pressures - one for the front tires and one for the rear tires - refer to the

Safety Compliance Certification Label or Tire Label which is located on the B-Pillar or the edge of the driver’s door. See Vehicle Loading in this chapter for more information.

Overview To provide the vehicle’s load carrying capability, some trucks require different recommended tire pressures in the front tires as compared to the rear tires. The Tire Pressure Monitoring System (TPMS) equipped on these vehicles is designed to illuminate the Low Tire Pressure Warning indicator at two different pressures; one for the front tires and one for the rear tires. Since tires need to be rotated to provide consistent performance and maximum tire life, the Tire Pressure Monitoring System needs to know when the tires are rotated to determine which set of tires are on the front and which are on the rear. With this information, the system can detect and properly warn of low tire pressures.

Always perform the TPMS reset procedure after tire rotation. If the system is not reset, it may not provide a low tire pressure

warning when necessary.

229

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

TPMS reset tool A special TPMS reset tool has been provided with your vehicle to reset your TPMS after tire rotation. The tool is located with your Owner’s Guide materials.

Please take the tool with the provided Velcro威 strip on the back and mount it in the bottom right corner of your Owner’s Guide case (as shown) for safe keeping. If you find that the reset tool was not provided when delivered, has been lost or no longer functions (the battery is not replaceable), please contact your authorized dealer to obtain a replacement. To verify that your TPMS reset tool is working, press and release the button on the center of the TPMS tool. The red light should illuminate and remain on for approximately five (5) seconds. If the light does not illuminate, the tool needs to be replaced. TPMS reset tips To reduce the chances of interference from another vehicle, TPMS reset should be performed at least three feet (one meter) away from another Ford Motor Company vehicle undergoing the TPMS reset procedure at the same time. Do not wait more than two (2) minutes between resetting each tire sensor or the system will timeout and the entire procedure will have to be repeated on all four wheels. A double horn chirp indicates the need to repeat the procedure. TPMS reset procedure Note: It is recommended that you read the entire procedure before attempting. Note: To enter the reset mode, Steps 1–5 MUST be completed within 60

seconds. 1. The key must be in the ignition and the ignition turned to OFF/LOCK. Press and release the brake pedal. 2. Cycle the ignition from OFF/LOCK to RUN three (3) times ending in the RUN position. DO NOT start the engine.230

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

3. Press and hold the brake pedal for two (2) seconds, then release. 4. Turn the ignition to OFF/LOCK (DO NOT remove the key.) 5. Cycle the ignition from OFF/LOCK to RUN three (3) times ending in RUN. DO NOT start the engine. If reset mode has been entered successfully, the horn will sound once, the TPMS indicator will flash and the message center will display TRAIN LF TIRE. If after repeated attempts to enter reset mode, the horn does not sound, the TPMS indicator does not flash and the message center does not display TRAIN LF TIRE, seek service from your authorized dealer. TPMS reset sequence The TPMS system needs to be reset starting with the left front tire in the following clockwise order: 1. Left front tire 2. Right front tire 3. Right rear tire 4. Left rear tire

231

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

1. Left front tire: Place the TPMS reset tool against the left front tire where the tire meets the rim, opposite from the valve stem (1) as shown. This is where the sensor is located inside the rim. The tool needs to be held against the tire sidewall opposite the valve stem as illustrated with the arrow on the tool pointing towards the rim; do not use the tool with the arrow pointing away from the rim as it may not activate the sensor. 2. Press and release the green button and hold the tool to the tire sidewall until the horn sounds. The red light on the TPMS reset tool will illuminate while the tool is active. The horn will sound once within 10

seconds to indicate the process was successful. Note: If a double horn chirp is heard, repeat the procedure. If a single horn chirp is not heard, move the vehicle to rotate the wheels at least a 1⁄4-turn and repeat the procedure. If the horn does not sound while attempting to reset any wheel, seek service from your authorized dealer. 3. Perform Steps 1 and 2 on the right front, right rear and finally the left rear tires. Successful completion of the reset procedure can be verified by turning the ignition to OFF without the horn sounding. If two short beeps are heard, the reset procedure was unsuccessful and must be repeated. If after repeating the procedure two short beeps are heard when the key is turned to OFF, seek assistance from your authorized dealer.232

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Rotation, pressure adjustment and TPMS reset example The following example describes all the major steps involved in rotating tires on a vehicle with different front and rear tire pressures. It illustrates that the TPMS reset procedure needs to follow tire rotation and pressure adjustment to avoid a possible false low tire warning. Example: A particular vehicle has the following recommended tire pressures: 50 psi (345 kPa) front; 80 psi (552 kPa) rear. Note: For your vehicle’s pressure, refer to the Safety Compliance Certification Label located on the B-Pillar or the edge of your vehicle’s driver’s door. Before tire rotation Sensor 1: 50 psi Sensor 2: 50 psi Sensor 3: 80 psi Sensor 4: 80 psi

Tire rotation using the recommended sequence (front tires at top of diagram)

233

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Sensor position following tire rotation Sensor 1: 50 psi Sensor 2: 50 psi Sensor 3: 80 psi Sensor 4: 80 psi

Pressure adjustment without the required TPMS reset procedure Sensor 1: 80 psi Sensor 2: 80 psi Sensor 3: 50 psi Sensor 4: 50 psi

In this situation, the TPMS warning light will come on.

If the TPMS reset procedure is not performed after tire rotation and air pressure adjustment, the TPMS telltale may illuminate for a false low tire pressure condition. As in this example, the rear tires rotated to the front and properly inflated to 50 psi (345 kPa) for the front axle would falsely illuminate the low tire warning indicator as they are still trained for the rear positions which require 80 psi (552 kPa).

234

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Rotation, pressure adjustment and successful completion of the TPMS reset procedure Sensor 1: 80 psi Sensor 2: 80 psi Sensor 3: 50 psi Sensor 4: 50 psi Tire rotation and air pressure adjustment followed by sensor resetting will ensure the system is properly programmed for vehicles with different front and rear tire pressures and reduce the risk of a false low tire warning. In this situation, the TPMS warning light will be off. SNOW TIRES AND CHAINS

Snow tires must be the same size and grade as the tires you currently have on your vehicle.

Note: Do not use snow chains on front tires of vehicles with 20” wheels and tires. The tires on your vehicle have all weather treads to provide traction in rain and snow. However, in some climates, you may need to use snow tires and chains. If you need to use chains, it is recommended that steel wheels (of the same size and specifications) be used, as chains may chip aluminum wheels. Follow these guidelines when using snow tires and chains: • Use only SAE Class S chains. • Install chains securely, verifying that the chains do not touch any • Drive cautiously. If you hear the chains rub or bang against your

wiring, brake lines or fuel lines.

vehicle, stop and re-tighten the chains. If this does not work, remove the chains to prevent damage to your vehicle.

• If possible, avoid fully loading your vehicle. • Remove the tire chains when they are no longer needed. Do not use • The suspension insulation and bumpers will help prevent vehicle damage. Do not remove these components from your vehicle when using snow tires and chains.

tire chains on dry roads.

235

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

VEHICLE LOADING – WITH AND WITHOUT A TRAILER This section will guide you in the proper loading of your vehicle and/or trailer, to keep your loaded vehicle weight within its design rating capability, with or without a trailer. Properly loading your vehicle will provide maximum return of vehicle design performance. Before loading your vehicle, familiarize yourself with the following terms for determining your vehicle’s weight ratings, with or without a trailer, from the vehicle’s Tire Label or Safety Compliance Certification Label: Base Curb Weight – is the weight of the vehicle including a full tank of fuel and all standard equipment. It does not include passengers, cargo, or optional equipment. Vehicle Curb Weight – is the weight of your new vehicle when you picked it up from your authorized dealer plus any aftermarket equipment.

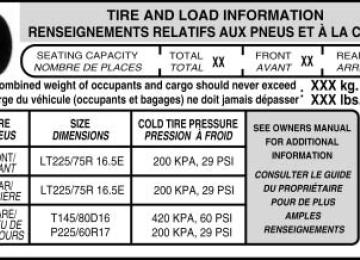

Payload – is the combined weight of cargo and passengers that the vehicle is carrying. The maximum payload for your vehicle can be found on the Tire Label (vehicles exported outside the U.S. and Canada may not have a Tire Label) on the B-Pillar or the edge of the driver’s door. Look for “THE COMBINED WEIGHT OF OCCUPANTS AND CARGO SHOULD NEVER EXCEED XXX kg OR XXX lb.” for maximum payload. The payload listed on the Tire Label is the maximum payload for the vehicle as built by the assembly plant. If any aftermarket or authorized dealer installed equipment has been installed on the vehicle, the weight of the equipment must be subtracted from the payload listed on the Tire Label in order to determine the new payload.

236

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

The appropriate loading capacity of your vehicle can be limited either by volume capacity (how much space is available) or by payload capacity (how much weight the vehicle should carry). Once you have reached the maximum payload of your vehicle, do not add more cargo, even if there is space available. Overloading or improperly loading your vehicle can contribute to loss of vehicle control and vehicle rollover.

Example only:

237

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Cargo Weight – includes all weight added to the Base Curb Weight, including cargo and optional equipment. When towing, trailer tongue load or king pin weight is also part of cargo weight. GAW (Gross Axle Weight) – is the total weight placed on each axle (front and rear) – including vehicle curb weight and all payload. GAWR (Gross Axle Weight Rating) – is the maximum allowable weight that can be carried by a single axle (front or rear). These numbers are shown on the Safety Compliance Certification Label located on the B-Pillar or the edge of the driver’s door. The total load on each axle must never exceed its GAWR.

Exceeding the Safety Compliance Certification Label axle weight rating limits could result in substandard vehicle handling or

performance, engine, transmission and/or structural damage, serious damage to the vehicle, loss of control and personal injury.

Note: For trailer towing information refer to Trailer towing found in this chapter or the RV and Trailer Towing Guide provided by your authorized dealer.

238

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

GVW (Gross Vehicle Weight) – is the Vehicle Curb Weight + cargo + passengers. GVWR (Gross Vehicle Weight Rating) – is the maximum allowable weight of the fully loaded vehicle (including all options, equipment, passengers and cargo). The GVWR is shown on the Safety Compliance Certification Label located on the B-Pillar or the edge of the driver’s door. The GVW must never exceed the GVWR.

GCW (Gross Combined Weight) – is the weight of the loaded vehicle (GVW) plus the weight of the fully loaded trailer. GCWR (Gross Combined Weight Rating) – is the maximum allowable weight of the vehicle and the loaded trailer – including all cargo and

239

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

passengers – that the vehicle can handle without risking damage. (Important: The towing vehicles’ braking system is rated for operation at GVWR, not at GCWR. Separate functional brakes should be used for safe control of towed vehicles and for trailers where the GCW of the towing vehicle plus the trailer exceed the GVWR of the towing vehicle. The GCW must never exceed the GCWR. Maximum Loaded Trailer Weight – is the highest possible weight of a fully loaded trailer the vehicle can tow. It assumes a vehicle with only mandatory options, no cargo (internal or external), a tongue load of 10–15% (conventional trailer) or king pin weight of 15–25% (fifth wheel trailer), and driver only (150 lb. [68 kg]). Consult your authorized dealer (or the RV and Trailer Towing Guide provided by your authorized dealer) for more detailed information. Tongue Load or Fifth Wheel King Pin Weight – refers to the amount of the weight that a trailer pushes down on a trailer hitch. Examples: For a 5,000 lb. (2,268 kg) conventional trailer, multiply 5,000

by 0.10 and 0.15 to obtain a proper tongue load range of 500 to 750 lb. (227 to 340 kg). For an 11,500 lb. (5,216 kg) fifth wheel trailer, multiply by 0.15 and 0.25 to obtain a proper king pin load range of 1,725 to 2,875 lb. (782 to 1,304 kg)Do not exceed the GVWR or the GAWR specified on the Safety Compliance Certification Label.

Do not use replacement tires with lower load carrying capacities than the originals because they may lower the vehicle’s GVWR and GAWR limitations. Replacement tires with a higher limit than the originals do not increase the GVWR and GAWR limitations.

Exceeding any vehicle weight rating limitation could result in serious damage to the vehicle and/or personal injury.

Steps for determining the correct load limit: 1. Locate the statement “The combined weight of occupants and cargo should never exceed XXX kg or XXX lbs.” on your vehicle’s placard. 2. Determine the combined weight of the driver and passengers that will be riding in your vehicle. 3. Subtract the combined weight of the driver and passengers from XXX kg or XXX lbs.

240

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

4. The resulting figure equals the available amount of cargo and luggage load capacity. For example, if the “XXX” amount equals 1,400 lbs. and there will be five 150 lb. passengers in your vehicle, the amount of available cargo and luggage load capacity is 650 lbs. (1,400–750

(5 x 150) = 650 lb.). In metric units (635–340 (5 x 68) = 295 kg.) 5. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not safely exceed the available cargo and luggage load capacity calculated in Step 4. 6. If your vehicle will be towing a trailer, load from your trailer will be transferred to your vehicle. Consult this manual to determine how this reduces the available cargo and luggage load capacity of your vehicle. The following gives you a few examples on how to calculate the available amount of cargo and luggage load capacity: • Another example for your vehicle with 1,400 lb. (635 kg) of cargo and luggage capacity. You decide to go golfing. Is there enough load capacity to carry you, 4 of your friends and all the golf bags? You and four friends average 220 lb. (99 kg) each and the golf bags weigh approximately 30 lb. (13.5 kg) each. The calculation would be: 1,400 – (5 x 220) – (5 x 30) = 1,400 – 1,100 – 150 = 150 lb. Yes, you have enough load capacity in your vehicle to transport four friends and your golf bags. In metric units, the calculation would be: 635 kg - (5 x 99 kg) - (5 x 13.5 kg) = 635 – 495 – 67.5 = 72.5 kg.• A final example for your vehicle with 1,400 lb. (635 kg) of cargo and luggage capacity. You and one of your friends decide to pick up cement from the local home improvement store to finish that patio you have been planning for the past 2 years. Measuring the inside of the vehicle with the rear seat folded down, you have room for 12-100 lb. (45 kg) bags of cement. Do you have enough load capacity to transport the cement to your home? If you and your friend each weigh 220 lb. (99 kg), the calculation would be: 1,400 – (2 x 220) – (12 x 100) = 1,400 – 440 – 1,200 = – 240 lb. No, you do not have enough cargo capacity to carry that much weight. In metric units, the calculation would be: 635 kg - (2 x 99 kg) - (12 x 45 kg) = 635 – 198

– 540 = – 103 kg. You will need to reduce the load weight by at least 240 lb. (104 kg). If you remove 3-100 lb. (45 kg) cement bags, then the load calculation would be: 1,400 – (2 x 220) – (9 x 100) = 1,400 – 440 – 900 = 60 lb. Now you have the load capacity to transport the cement and your friend home. In metric units, the calculation would be: 635 kg - (2 x 99 kg) - (9 x 45 kg) = 635 – 198 – 405 = 32 kg.241

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

The above calculations also assume that the loads are positioned in your vehicle in a manner that does not overload the Front or the Rear Gross Axle Weight Rating specified for your vehicle on the Tire Label or Safety Compliance Certification Label found on the edge of the driver’s door.

Special loading instructions for owners of pickup trucks and utility-type vehicles

For important information regarding safe operation of this type of vehicle, see the Preparing to drive your vehicle section in

the Driving chapter of this owner guide.

Loaded vehicles may handle differently than unloaded vehicles. Extra precautions, such as slower speeds and increased stopping

distance, should be taken when driving a heavily loaded vehicle.

Your vehicle can haul more cargo and people than most passenger cars. Depending upon the type and placement of the load, hauling cargo and people may raise the center of gravity of the vehicle.

TRAILER TOWING Note: The trailer towing charts in this section apply to vehicles equipped with gasoline engines; for vehicles equipped with diesel engines, refer to your 6.0 and 6.4 Liter Power Stroke Direct Injection Turbo Diesel Owner’s Guide Supplement. Your vehicle may tow a Conventional/Class IV trailer or fifth wheel trailer provided the maximum trailer weight is less than or equal to the maximum trailer weight listed for your engine and rear axle ratio on the following charts. To calculate your maximum trailer weight: For pickup trucks: Take curb weight, hitch hardware and the driver’s weight, then subtract them from the GCWR listed for your vehicle series, engine, transmission and drive axle ratio (refer to the chart/table in the following text). This calculation will give you the maximum trailer weight possible for your vehicle. For chassis cabs and pickup trucks with aftermarket equipment: Weigh your vehicle at a certified scale and subtract this actual curb weight, hitch hardware, and the driver’s weight from the GCWR listed for your vehicle series, engine, transmission and drive axle ratio (refer to the chart/table in the following text). This calculation will give you the maximum trailer weight possible for your vehicle.

242

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

The weight of all additional cargo and passengers must be subtracted from the maximum trailer weight calculated above. Further trailer/hitch restrictions and limitations exist depending on the type of trailer and hitch used. These additional maximum trailer weight and tongue load limitations are listed in the chart/table that follows the listing of GCWRs. Towing a trailer places an additional load on your vehicle’s engine, transmission, axle, brakes, tires and suspension. Inspect these components carefully prior to and after any towing operation. Refer to Transmission fluid temperature gauge in the Instrument Cluster chapter for the transmission fluid temperature information. Note: Do not exceed the GCWR listed for your vehicle on the following chart/table, or the GVWR, GAWR or tire ratings specified on the Tire Label or Safety Compliance Certification Label.

Towing trailers beyond the maximum recommended trailer weight which exceeds the limit of the vehicle’s GCWR, GVWR,

GAWR or tire ratings could result in engine damage, transmission damage, structural damage, loss of vehicle control, vehicle rollover and personal injury.

Maximum GCWR - lb. (kg.)

Engine

Rear axle

ratio

Manual

transmission

Automatic

transmission

5.4L

6.8L

5.4L

6.8L

F–250 Pick-up

3.73

4.10

4.10

4.3015000 (6804) 17000 (7711) 20000 (9072) 22000 (9979)

16000 (7257) 18000 (8165) 21000 (9525) 22500 (10206)

F–350 Single Rear Wheel (SRW) Pick-up

3.73

4.10

4.10

4.3015000 (6804) 17000 (7711) 20000 (9072) 22000 (9979)

16000 (7257) 18000 (8165) 21000 (9525) 23000 (10433)

243

2008 F-250/350/450/550 (f23) Owners Guide (post-2002-fmt) USA (fus)

Tires, Wheels and Loading

Maximum GCWR - lb. (kg.)

Engine

Rear axle

ratio

Manual