Rb25/30det Engine Build, Need More Info? - what machining is needed on the 25 head & the 30 block???

|

Post #1

17th January 2011 - 01:57 PM 17th January 2011 - 01:57 PM

|

|

|---|---|

|

hey guys so i'm looking at doing a rb25/30det engine build & want to get some more info before i start. so what kind of machining is needed on the s2 R33 rb25det head & also on the rb30 block to make this fit? i'm also going to get stronger piston, rings, crank etc etc any info would be great... thanx |

|

|

|

iamhappy46

Post #3

Stock RB30 N/A pistons, rods and crank are good for around 400rwHp since the 35 head drops compression to a much more boost friendly 8.3:1 |

|---|

|

|

blown7

Post #4

Stock RB30 N/A pistons, rods and crank are good for around 400rwHp since the 35 head drops compression to a much more boost friendly 8.3:1 Skylines Australia website has a complete walk though on the conversion, it is not hard with tapping the block for the extra timing belt pulleys about as hard as it gets ok sweet what about VCT do i block that off on the head or block? then run an external line from somewhere? you wouldn't know the link on SAU would you? as i dont have an account there.... cheers |

|---|

|

|

blown7

Post #7

ok so i've sourced an already built rb30 block that has previously been used for the rb25/30det set up before so all the work has been done to the 30 block, nothing i need to get machined on that. |

|---|

|

|

TwinCam16

Post #8

ok so i've sourced an already built rb30 block that has previously been used for the rb25/30det set up before so all the work has been done to the 30 block, nothing i need to get machined on that. I currently have s2 R33 rb25det head so the question is what machining need to be done to that to make it fit onto the rb30 block? whats the best way to go with the VCT? i've been told it may have to be welded, where does it have to be welded on the block or head? & do i have to still run en external oil line for that??? cheers Do yourself a favor, and start a new thread. |

|---|

|

|

iamhappy46

Post #12

If your not using the VCT, then nothing needs to be welded up. Just converted to adjustable cams gears to get rid of the VCT solenoid cam gear |

|---|

|

|

stephen16

Post #14

As far as I have researched there is no machining to be done, you grab a rb30 block, and slap the head on, tap the hole for the timing belt adjuster, and turbo oil lines if you don't have a s2 block |

|---|

|

|

iamhappy46

Post #15

You could cap it, although most of the time I have just left the VCT solenoid unplugged, since the headgasket design means nothing is going to get in at that end anyway as the RB30 block has not have an oil feed at that point and since the VCT is blocked off, there will be no oil pressure control problems anyway. |

|---|

|

|

blown7

Post #16

You could cap it, although most of the time I have just left the VCT solenoid unplugged, since the headgasket design means nothing is going to get in at that end anyway as the RB30 block has not have an oil feed at that point and since the VCT is blocked off, there will be no oil pressure control problems anyway. ok sweet would there be anything else i'd need to know or look out for when putting it all together? also i did source an already built rb30 block thats had a rb25 head bolted on. just need to know if i'm missing any info on the head side of things now. if not i''m pretty much set... |

|---|

|

|

09ONE

Post #22

If your not using the VCT, then nothing needs to be welded up. Just converted to adjustable cams gears to get rid of the VCT solenoid cam gear If you want to use VCT, then it is a little more involved Depends on what head gasket he uses. If using an RB30 one then no its fine as this will cover the hole but a RB25 head gasket will have the hole cut into it. Either way I would be welding the oil feed for the VCT up in the head. For oil pumps you should be using a NEW RB26 pump at a mimimum with a properly machined crank collar as the RB30 Crank doesnt not extent into the pump drive far enough. Dont use a N1 pump they are fragile as fuck. Make sure you also enlarge the oil drain backs from the head and definately use oil restrictors 1.2mm in the feed to the head. Ceramic coating the piston crowns is a good idea because fitting oil squirters to the RB30 block is near on impossible due to casting irregularities. |

|---|

|

|

blown7

Post #23

Depends on what head gasket he uses. If using an RB30 one then no its fine as this will cover the hole but a RB25 head gasket will have the hole cut into it. Either way I would be welding the oil feed for the VCT up in the head. For oil pumps you should be using a NEW RB26 pump at a mimimum with a properly machined crank collar as the RB30 Crank doesnt not extent into the pump drive far enough. Dont use a N1 pump they are fragile as fuck. Make sure you also enlarge the oil drain backs from the head and definately use oil restrictors 1.2mm in the feed to the head. Ceramic coating the piston crowns is a good idea because fitting oil squirters to the RB30 block is near on impossible due to casting irregularities. yeah using an rb30 head gasket i guess. but i'm still going to block or weld the oil feed... the crank already has a collar on it, new one unsure what sort tho kinda looks like a stock one so i'm guessing my rb25 oil pump will be fine to use on it? |

|---|

|

|

blown7

Post #27

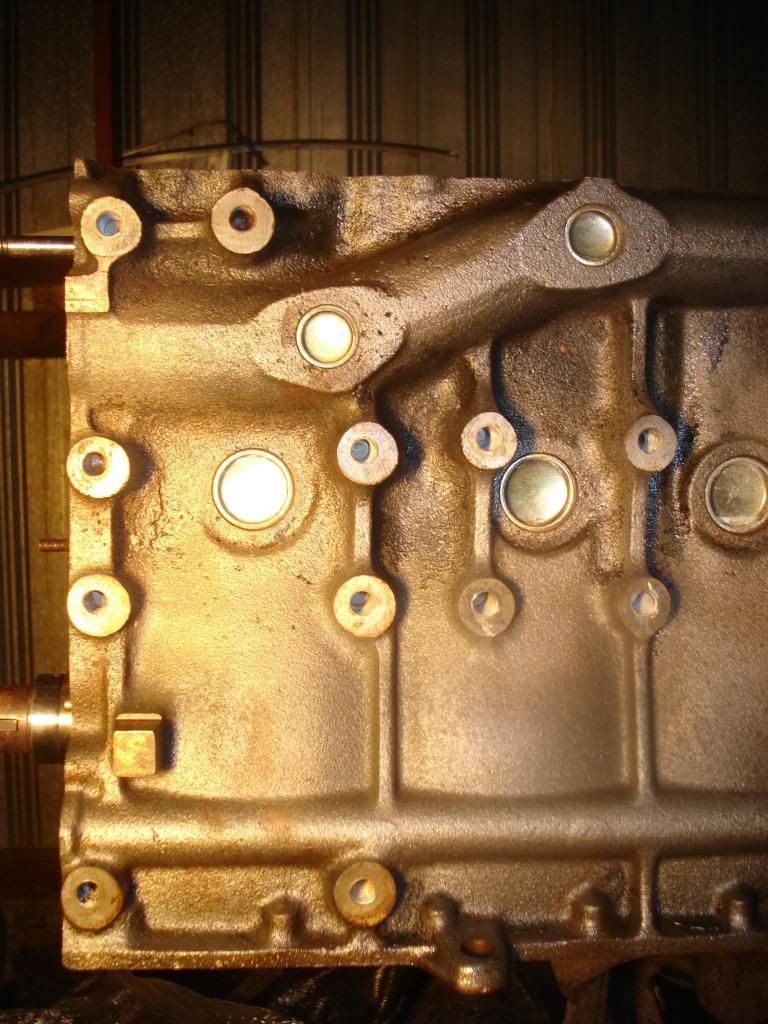

i've just noticed on the rb25det there are an extra line from the head running to the block. what could these be used for? & what do i do with it as the rb30 block doesn't have a tapped hole on the block to fit it... |

|---|

-

Member Login

If you have a BoostCruising account enter your user name and password into the yellow box.

Alternatively, you can quickly login with Facebook.

If you don't have an account create one below.

Create Account -

Login using your Facebook account!